Small electric motors serve as the unsung heroes in our daily lives, quietly powering an array of household appliances, tools, and even cutting-edge automobiles. These seemingly trivial components are integral to auxiliary systems, driving functions like pumps and ventilation fans. Each motor, taken in isolation, appears to have a minor energy footprint. However, when their collective impact is considered, the potential for energy savings becomes significant. A recent exploration into this realm by the innovative research team of the “CD Laboratory for Brushless Drives for Pump and Fan Applications” at Graz University of Technology has unveiled pathways to dramatically enhance the energy efficiency and overall performance of these indispensable devices.

Under the leadership of Annette Mütze, the research team has pioneered an approach that combines cutting-edge design modifications, advanced control technologies, and new manufacturing techniques. Their efforts focus on brushless integrated drives, which offer a multifaceted suite of benefits: reduced energy consumption, decreased operational noise, and lighter weight. One of their notable achievements is the reengineering of claw pole motors, commonly used in vehicle lighting systems but often overlooked as compact drive units. By strategically skewing and slotting the claw components, the team has successfully diminished “cogging torque,” a phenomenon that can lead to jarring vibrations during motor operation. This novel adjustment minimizes the physical engagement of the motor’s claws, significantly contributing to a 70% reduction in noise—a feat that not only enhances user comfort but also indicates a smoother motor operation.

An additional triumph lies in the optimization of current flow regulation within these motors. Traditional methods depend heavily on pulse width modulation (PWM), which requires numerous switching operations to maintain the desired current profile. While PWM is effective, the energy waste incurred during these switches can detract from overall efficiency. Remarkably, the research team’s innovative strategy involves only activating the motors at a singular on-off toggle per desired control rectangle. This streamlined approach means that they have curtailed the unnecessary energy consumed during switching, particularly improving efficiency at lower currents.

As a result of fewer switching actions, the circuit boards that serve as the operational core of these motors have also benefitted. With a reduced need for components, such as capacitors, overall manufacturing costs subsequently see a significant downturn. Simplifying the components not only paves the way for cost-effective solutions but also alleviates the weight, contributing further to a sophisticated design.

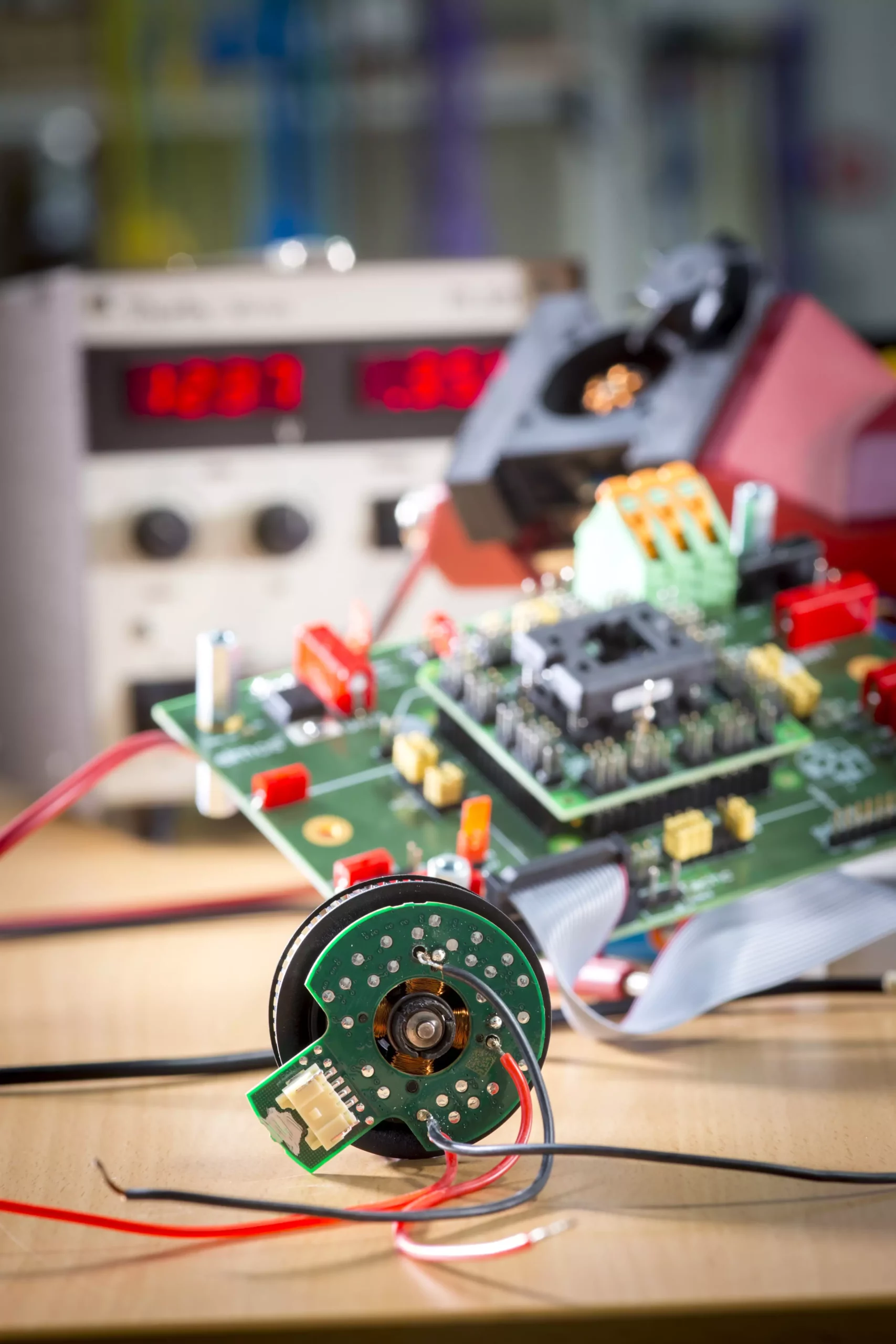

A standout innovation from Mütze’s team includes the introduction of printed circuit board (PCB) motors. In this design, the essential windings that create the magnetic field necessary for motor function are integrated directly into the printed circuit board. This modern manufacturing concept allows for unprecedented automation, enhancing production efficiency. The incorporation of 3D-printed ferrite cores on these circuit boards has further propelled the design forward. The addition not only facilitates improved magnetic flux management within the motors but also allows the usage of more affordable ferrite-based magnets. This adaptation underscores a functional duality: enhanced performance qualities are achieved simultaneously with reductions in material costs.

Ultimately, these breakthroughs represent a significant leap forward in the design and functionality of small electric motors. As the world increasingly shifts towards sustainability, the innovations introduced by Mütze’s team at Graz University of Technology showcase how even seemingly modest components can yield monumental efficiency gains. Their approach to reducing noise, simplifying control mechanisms, and reimagining production techniques signifies a robust commitment to advancing energy-efficient technologies that could ripple across industries, from household applications to automotive systems. As these innovations gain traction, they promise not only cost savings but also a pivotal role in achieving broader environmental goals.