In modern technological applications spanning nuclear energy systems to military endeavors, the importance of materials engineered for extreme environments cannot be understated. These materials must exhibit robustness under conditions involving high pressure, elevated temperatures, and corrosive environments. As industries strive for innovation, the quest for next-generation materials that are lighter, more affordable, yet sustainable has become paramount. At the heart of this advancement lies a deep understanding of how materials behave at the atomic level when subjected to severe stress conditions.

Researchers at the Lawrence Livermore National Laboratory (LLNL) have made significant strides in this area through their latest experimentation with zirconium, a metal renowned for its strength and durability. In their groundbreaking study, published in prestigious journals such as Physical Review Letters and Physical Review B, the team found that when compressed under high pressure, zirconium displayed intricate deformation behaviors that defied previous expectations. The mechanisms identified included phenomena such as dislocation slip, phase transitions, and unexpected crystallographic twinning.

The multidimensional interaction of these mechanisms is essential for engineers and scientists as they produce predictive models aimed at enhancing material performance under extreme conditions. According to lead researcher Saransh Soderlind, understanding these microscopic changes is key to designing materials that can sustain dramatic shifts in structural integrity without failure.

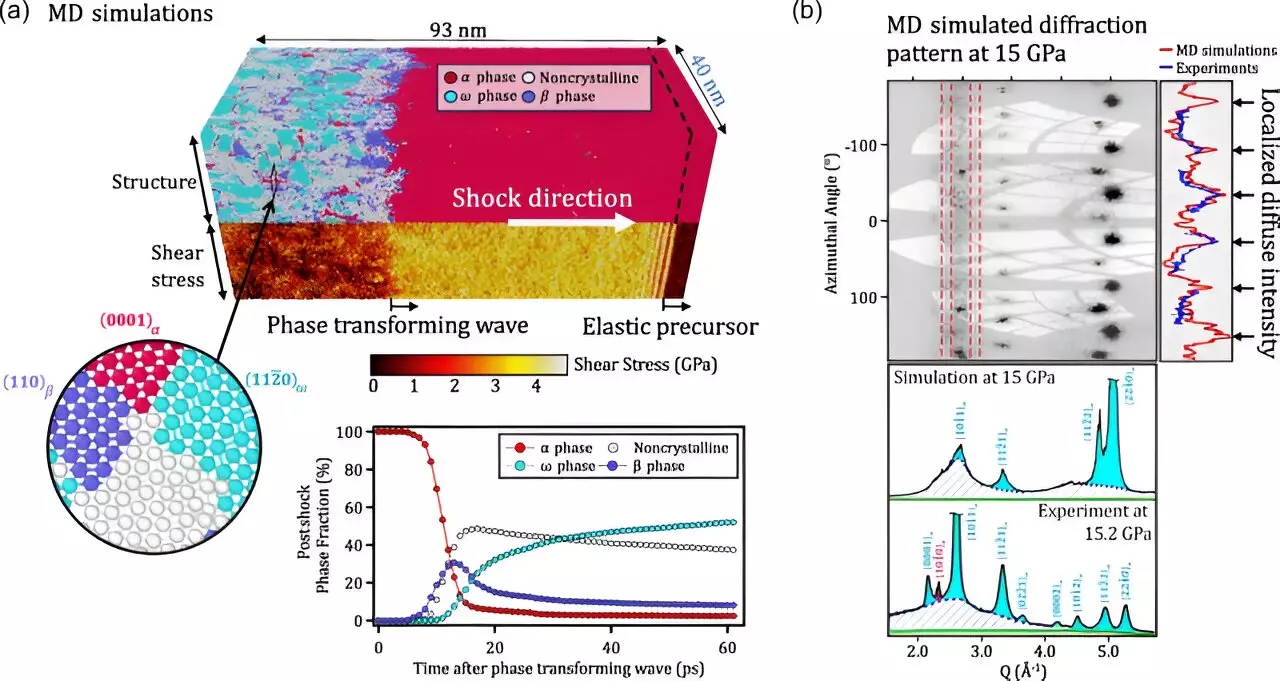

The team’s innovative approach utilized femtosecond in-situ X-ray diffraction to study single-crystal zirconium. This cutting-edge technique allowed them to capture the metal’s behavior at nanosecond intervals, providing a real-time glimpse into the atomic dynamics associated with high pressure. Disruptions in atomic order were observed, revealing complexities that had not been previously recorded in elemental metals.

Interestingly, the research also unveiled several phase transition pathways for zirconium, marking a first in the scientific literature. Such revelations underscore the necessity of investigating materials under conditions simulating their intended applications rather than relying solely on theoretical models or studies involving polycrystalline specimens.

The findings from LLNL not only deepen our understanding of zirconium’s behavior but also suggest underlying principles applicable to a broader variety of materials. The rich tapestry of atomic movements observed could be indicative of behavior in other elemental metals when subjected to similar extreme conditions. As noted by LLNL scientist Raymond Smith, this study provides a more nuanced insight into metal deformation than previously recognized.

Moreover, zirconium’s established use in the nuclear industry as cladding for fuel rods showcases the real-world significance of such research. Its low neutron absorption and high strength make it indispensable in contexts that demand dependable performance despite harsh conditions.

As we stand on the threshold of new material development, insights gained from studies like this serve as crucial stepping stones. Understanding the intricate behaviors of materials like zirconium not only drives technological advancement in industries critical to energy and security but also ushers in a new era of materials engineering characterized by resilience and efficiency. The journey to innovate and develop next-generation materials is a multifaceted endeavor, and this research lays an important foundation for future explorations in the field.