From the earliest days of civilization, blacksmiths recognized that manipulating metal through techniques such as hammering and bending could enhance its strength. This ancient practice has its roots in the Bronze and Iron Ages, where the art of metallurgy transformed societies by allowing stronger tools and weapons to be produced. The process known as work or strain hardening, which refers to the increase in strength that occurs when metals are deformed, continues to play a pivotal role in modern manufacturing practices. As fundamental as these techniques may seem, limitations have hindered scientists from observing the real-time mechanics behind work hardening—until recent advances opened the door to novel insights.

Recent research from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) has crossed a significant threshold by allowing for the real-time observation of work hardening processes. Under the auspices of the Harvard Materials Research Science and Engineering Center (MRSEC), this groundbreaking study delves into the intricate mechanisms that define material strength. Published in the prestigious journal Nature, the findings promise to reshape our understanding of material behavior and could influence future developments in material design and manufacturing.

Frans Spaepen, a senior author of the study and a notable figure in the field of applied physics, stated, “Today, large-scale computer models are employed to interpret work hardening, but the effectiveness of these models is directly tied to our comprehension of the underlying principles that dictate this process.” This sentiment underscores the importance of understanding the atomic-level events that contribute to work hardening, especially as we continue to refine predictive models in material science.

The Quest for Real-Time Observation

Historically, the study of work hardening has been hampered by technological limitations. Specifically, the atomic structures of metals are only observable via electron microscopy, thus restricting researchers to comparing pre- and post-deformation states rather than witnessing the transformations as they occur. Previous research consistently indicated that dislocations—imperfections in the atomic structure—played a significant role in the ensuing work hardening. However, the operational dynamics of these dislocations remained somewhat elusive.

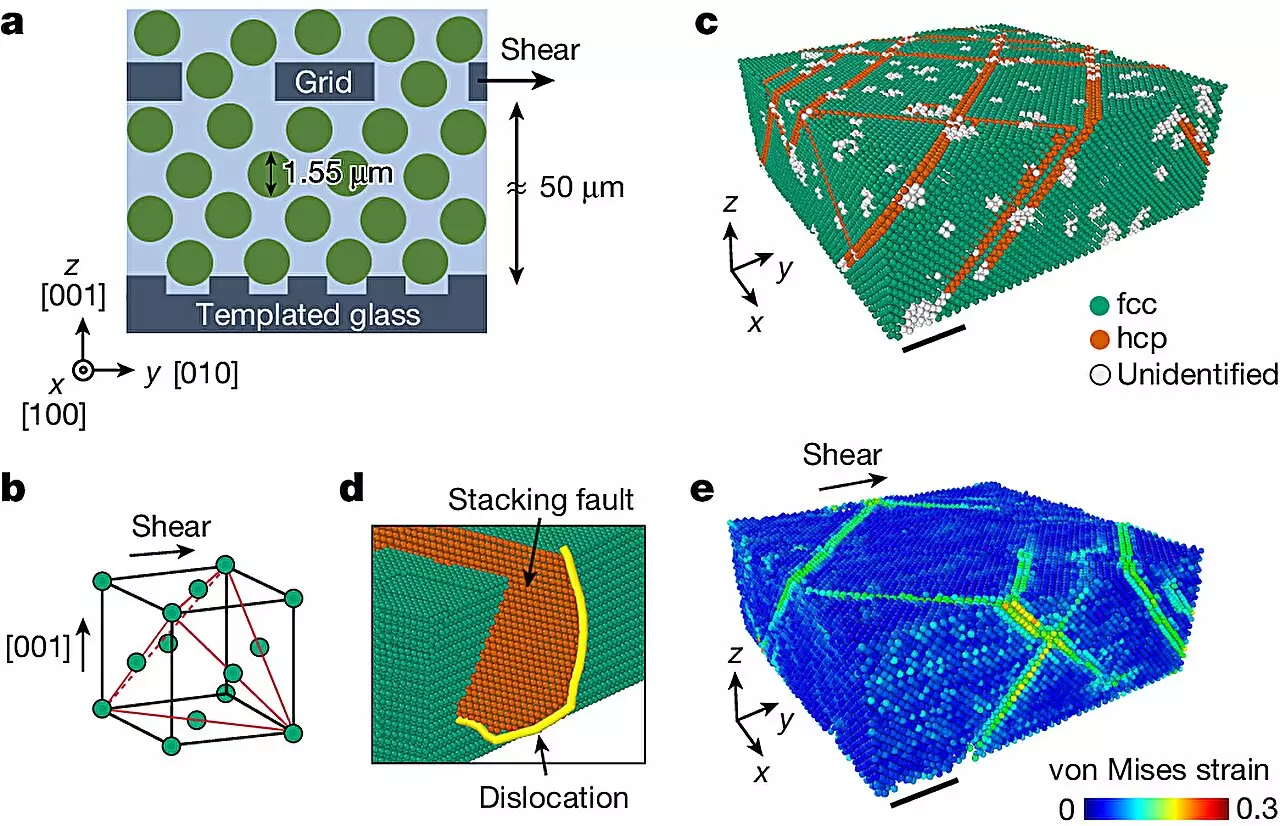

To garner greater insight into this crucial phase of material deformation, the researchers turned to colloidal crystals. These crystals feature particles significantly larger than atoms, yet they simulate atomic systems accurately due to their comparable structural properties. Such a method allowed the team to observe particle movements in real-time with the aid of a confocal optical microscope. What they uncovered was astonishing: these colloidal structures exhibited remarkable work hardening traits, exceeding those seen in many conventional metals.

The study revealed that colloidal crystals, consisting of millions of particles, can experience far-reaching effects of work hardening—this phenomenon was entirely unexpected. Co-first author Seongsoo Kim expressed surprise at the results, stating, “We initially believed that the interactions among these harmless particles would be far too simplistic compared to heavier metals. However, we discovered that these soft materials displayed an exaggerated form of work hardening, even surpassing the capabilities of metals such as copper and aluminum.”

This finding indicates that work hardening is not just confined to traditional hard materials but is also applicable to soft colloidal structures. This offers a new lens through which to view material strength—not just based on inherent toughness but by how particles interact and become entangled.

One of the study’s most significant themes is the idea that the mechanisms governing work hardening are universal. The interactions between dislocations and their geometric configurations proved to be a cornerstone for explaining this behavior. This newly gleaned understanding could extend beyond colloidal crystals, providing a foundational principle applicable to a wide array of materials, including those that have yet to be observed through conventional means.

The research conducted at Harvard has uncovered extraordinary insights into the nature of work hardening, suggesting that even the softest materials can possess remarkable strength when subjected to deformation processes. As David A. Weitz, another co-author, aptly remarked, “These materials, despite their softness, challenge our traditional notions of strength, proclaiming a new paradigm within material science.” The implications of this study are likely to resonate for years to come, ushering in advancements that could redefine the limits of material performance in numerous applications.