Plastic pollution, a pervasive environmental crisis, demands innovative solutions for effective waste management and recycling. With billions of tons of plastic waste accumulating globally, conventional recycling techniques fall short, especially in the realm of chemical recycling. A research initiative spearheaded by Professor Kotohiro Nomura from Tokyo Metropolitan University aims to tackle this issue by introducing an efficient method for the depolymerization of polyethylene terephthalate (PET)—a common plastic material found in consumption goods ranging from bottles to textiles. By employing readily available iron trichloride as a catalyst, this technique marks a promising advance in sustainable recycling practices.

Polyethylene terephthalate is primarily utilized for its versatility, affordability, and durability in various applications. However, its structural complexity, characterized by ester bonds formed from the reaction of carboxylic acids and alcohols, complicates the recycling process. Traditional chemical recycling methods are often restricted by the necessity for high temperatures and corrosive acidic or basic reagents, making them expensive and logistically challenging. The pressing need for an economical and environmentally responsible alternative has catalyzed extensive research into novel depolymerization processes.

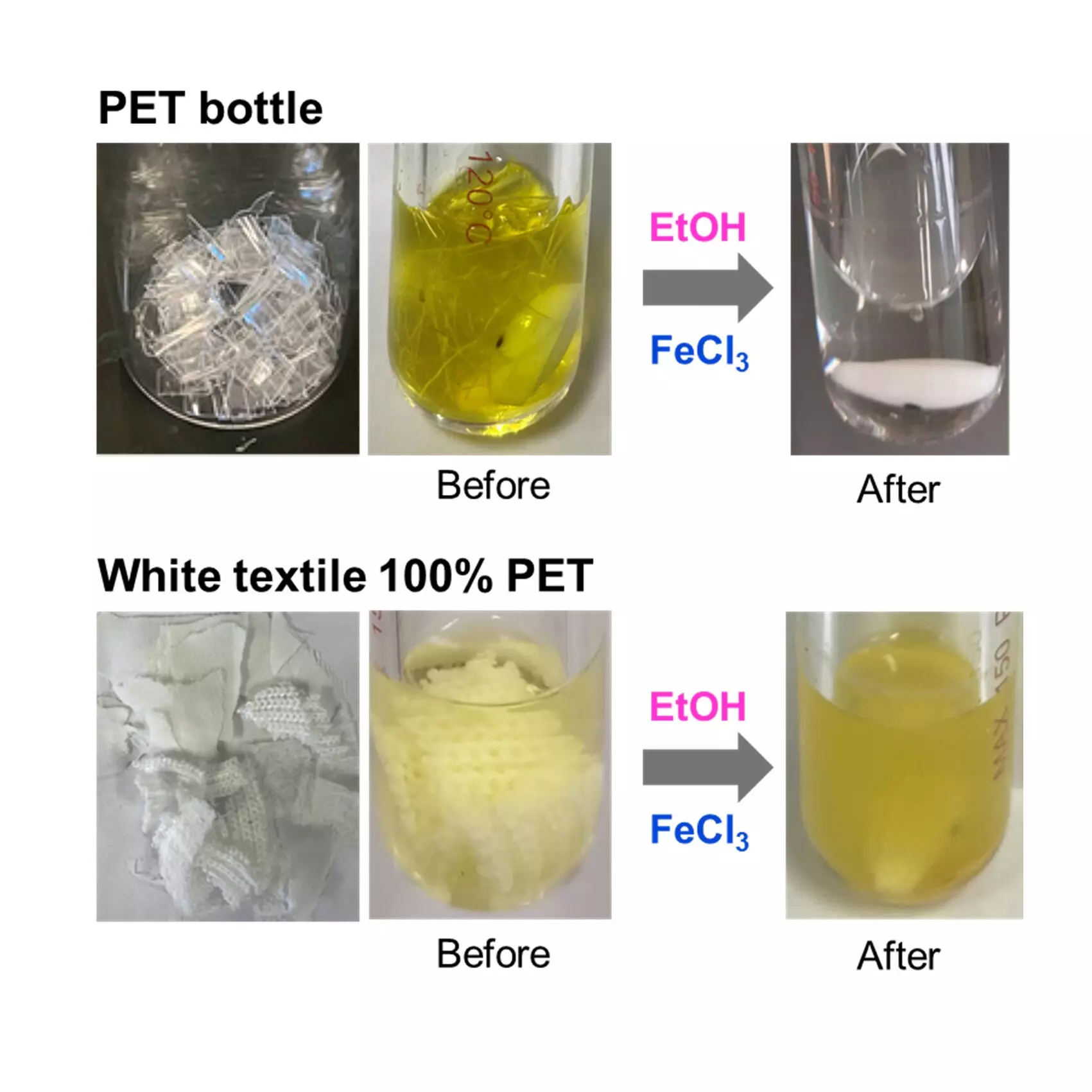

The innovative approach presented by Professor Nomura’s team utilizes ethanol, alongside iron trichloride, to efficiently break down PET into its fundamental components—diethyl terephthalate (DET) and ethylene glycol (EG)—at comparatively moderate temperatures of 160–180°C. This method boasts an impressive selectivity rate of 98–99%, outperforming previous techniques reliant on more costly titanium catalysts. The application of iron catalysts not only enhances the efficiency of the process but also underscores the potential for transitioning to a more sustainable, circular economy through accessible resources.

One of the significant challenges in plastics recycling is the presence of mixed materials, particularly within textile waste that often contains a blend of polyester and natural fibers like cotton. The developed method successfully addresses this challenge by enabling the selective depolymerization of PET from composite waste. Remarkably, as PET is broken down into DET and EG, the cotton is recovered in a negligible waste stream, ensuring that valuable resources are preserved. This development is crucial, as textile waste is among the fastest-growing segments of global waste, making effective recycling strategies imperative for sustainable development.

The research team’s efforts not only represent a significant stride towards resolving the plastic waste crisis but also provide a replicable framework for other recycling initiatives aiming to recover valuable materials from waste streams efficiently. As industries and consumers become increasingly aware of the importance of sustainable practices, solutions like this novel depolymerization method could be vital in diminishing the environmental burden of plastic waste, fostering a more sustainable circular economy for the future. The significance of this research encourages ongoing innovation in the field of chemical recycling, paving the way for a cleaner and more responsible approach to material management.