Researchers at the FAMU-FSU College of Engineering have developed a pioneering biomass-derived material that has the potential to significantly address the pressing issue of carbon dioxide (CO2) capture and release. This novel material, primarily composed of lignin—a complex organic polymer found in the cell walls of plants—stands out for its ability to efficiently absorb CO2 from either concentrated sources or ambient air. The study detailing these findings was published in the prestigious journal Advanced Materials, marking a notable advancement in environmental engineering and materials science.

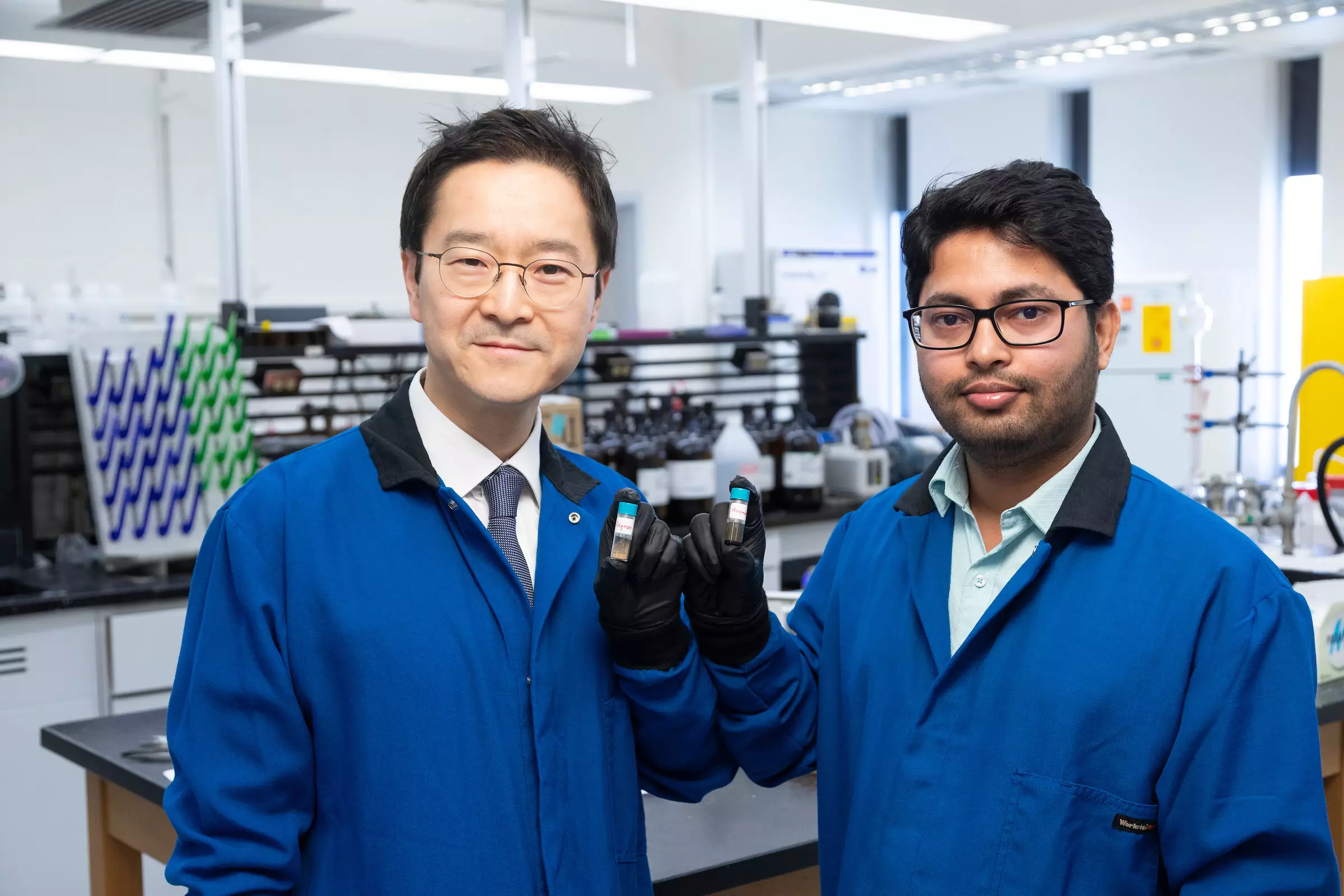

The core advantage of this new lignin-based material lies in its remarkable capacity for CO2 management without the need for extreme operational conditions. Hoyong Chung, the study’s co-author and an associate professor at the FAMU-FSU College of Engineering, emphasizes that this innovation allows for controlled CO2 absorption and release under mild conditions, eliminating the reliance on high pressure or elevated temperatures commonly found in traditional carbon capture methods. This characteristic not only enhances the feasibility of using the material in real-world applications but also opens doors for scaling up its production.

This innovative approach isn’t entirely new; it builds upon previous research conducted by Chung’s team, which explored the potential of lignin-based polymers as alternatives to conventional petroleum-derived plastics. The earlier work exhibited the versatility of lignin in creating sustainable materials. This current research further extends that foundation, demonstrating the capacity for the material to revert to its original state after use, enabling repeated CO2 capture cycles. Such a property is vital for long-term environmental applications where durability and recyclability are paramount.

Quantitatively, the study reports that one gram of this new material can absorb approximately 47 milligrams of CO2 from high-concentration sources and 26 milligrams from open-air environments. This efficiency highlights the material’s potential to be integrated within various sectors, including manufacturing and agriculture. Moreover, the ability to sequester the captured carbon permanently or release it for use in secondary applications poses a dual benefit—either mitigating greenhouse gas emissions or utilizing CO2 in innovative ways.

A particularly fascinating aspect uncovered during research was the mechanism of CO2 release. Utilizing nuclear magnetic resonance spectroscopy allowed researchers to observe the unexpected formation of gas bubbles when the material was heated. This observation led to deeper investigations, revealing that CO2 could be released by applying heat—an insight that enhances the understanding of how the material functions at a molecular level. This controllable release mechanism allows for the adjustment of CO2 output between varied temperatures, providing adaptability for different applications and scenarios.

The ingenuity of this lignin-based material positions it as a versatile “sponge” for CO2. Its unique properties, including the ability to absorb, release, and reabsorb CO2, make it an exciting prospect for companies and governments aiming to address carbon emissions in a sustainable, cost-effective manner. As the world grapples with the consequences of climate change, innovations like this offer not only hope but also practical solutions for future environmental sustainability. The research distilled from Chung’s team, led by postdoctoral researcher Arijit Ghorai, marks a significant milestone in enhancing the circular economy of carbon management and signifies the importance of rethinking material utilization in the quest for a greener planet.