High-temperature superconducting (HTS) wires represent a technological frontier that holds immense promise for improving how we generate, transmit, and utilize electricity. Unlike conventional superconductors that operate close to absolute zero, HTS wires can function at significantly higher temperatures—though still frigid by everyday standards—potentially transforming our energy landscape. This innovation could pave the way for advancements such as ultra-efficient electric grids or even sustainable commercial nuclear fusion, tackling one of humanity’s most pressing challenges—clean energy generation.

However, for HTS technology to be embraced on a large scale, its fabrication must become economically viable—achieving a price-performance ratio comparable to traditional copper wiring, commonly found in hardware stores. Recent research spearheaded by a team at the University of Buffalo is making noteworthy strides toward this critical goal, with implications that could resonate throughout multiple sectors.

Groundbreaking Research and Achievements

In a study recently published in *Nature Communications*, the University at Buffalo’s researchers revealed their achievement of the highest-performing segment of HTS wire ever fabricated. Based on rare-earth barium copper oxide (REBCO), these wires excelled in both critical current density and pinning force—integral metrics that dictate their performance. The wires maintained exceptional performance across various conditions, effectively establishing benchmarks in their category.

Amit Goyal, Ph.D., the lead researcher, articulates the significance of these findings, noting their potential to shape industry strategies toward more efficient manufacturing processes. By enhancing the price-performance metric, we edge closer to unleashing the myriad applications HTS technology can offer, from revolutionized energy grids to game-changing medical imaging devices.

A Myriad of Applications

The applications for HTS wires are diverse and promising. They could drastically improve energy generation, allowing for enhanced output from renewable sources like offshore wind farms. The ability to transmit high amounts of electricity without loss presents an enticing prospect for energy grids built on sustainability and efficiency. Moreover, HTS wires could lead to groundbreaking developments in energy storage technologies, enabling instantaneous power availability and bolstering grid reliability.

Commercial nuclear fusion stands out as a particularly transformative application. With an influx of private investment into fusion technology and the race toward operational fusion reactors, HTS wires could prove critical in achieving safe, limitless energy. The energy landscape could forever alter, granting society unprecedented access to clean energy sources, provided the technology matures to meet demand effectively.

The Technological Journey

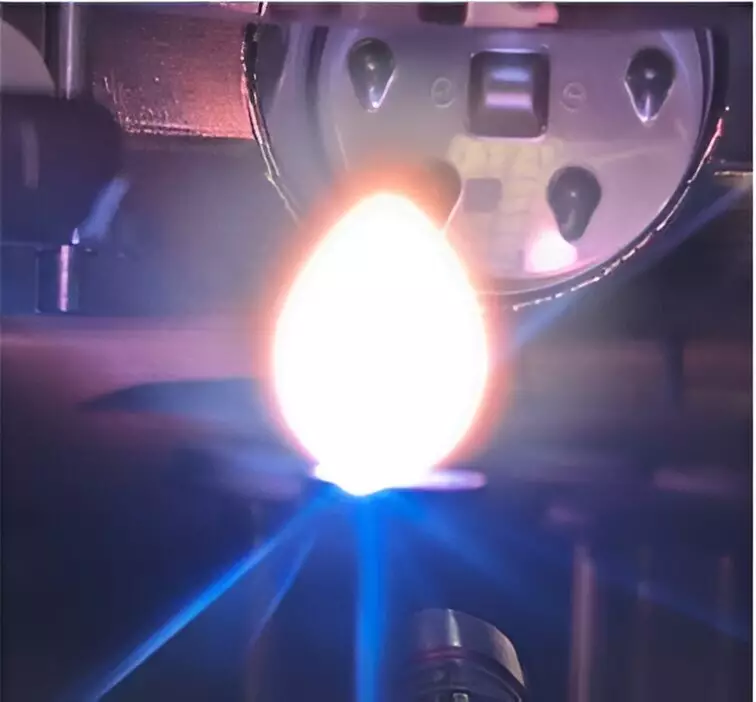

The route to achieving these technological milestones is multifaceted, often involving complex engineering and material science innovations. Goyal’s team employs various advanced fabrication techniques, including rolling assisted biaxially textured substrates (RABiTS) and innovative deposition technologies that harness microscopic defects to enhance wire performance.

Details of their latest work underscore the achievement’s significance: Even with a minimal thickness of 0.2 microns, their HTS wires outperformed conventional thicker competitors, highlighting the advantages of precision engineering in the field. The wires showed remarkable ability to carry large currents under both self-field and magnetic field conditions, establishing new records that other researchers will aim to surpass.

Building a Framework for Future Development

The implications of these advancements go beyond mere energy applications; they could alter defense and medical domains as well. From all-electric ships to ultra-sensitive MRI machines, the integration of HTS wires can redefine efficiency and capability in various sectors. The cutthroat competitive atmosphere in private sector innovations—spurred by significant investments aimed at achieving operational milestones in fusion energy—further accelerates the development of cost-effective HTS wire solutions.

Yet, this journey is still in its infancy. While the technological underpinnings are rapidly advancing, the critical need is for industries to harness these findings effectively. The research led by the University at Buffalo has drawn attention to the need for optimized manufacturing processes and collaborative efforts to iron out the remaining challenges toward commercialization.

Looking Ahead: The Road to Mass Implementation

End-users and industries alike are brimming with anticipation regarding the commercial rollout of HTS wires. The barriers to implementation include not just technical challenges but also supply chain logistics and market readiness. With significant funding and interest from multiple global players, it is clear that the race for widespread application of HTS technology could soon escalate.

In essence, the quest for efficient energy transmission and generation through HTS wires is not merely an academic pursuit—it is a necessary step toward a sustainable future. As advancements continue, the electric grid’s transformation into a more efficient organism becomes not just a dream but a feasible reality. The informed optimism surrounding HTS technology suggests that we are on the precipice of an energy revolution, one that could eliminate longstanding barriers to clean and efficient power.