As the world aggressively pursues sustainable energy solutions to combat climate change, green hydrogen emerges as a beacon of hope. This clean energy source, derived from water using renewable energy sources like solar and wind, offers remarkable potential to decarbonize numerous sectors, including transportation, industry, and power generation. The U.S. Department of Energy envisions that green hydrogen is pivotal for achieving a net-zero carbon footprint, paving the way for a sustainable future. However, while the promise of green hydrogen is profound, practical challenges remain in harnessing this clean fuel efficiently and affordably.

Current Technological Challenges in Hydrogen Production

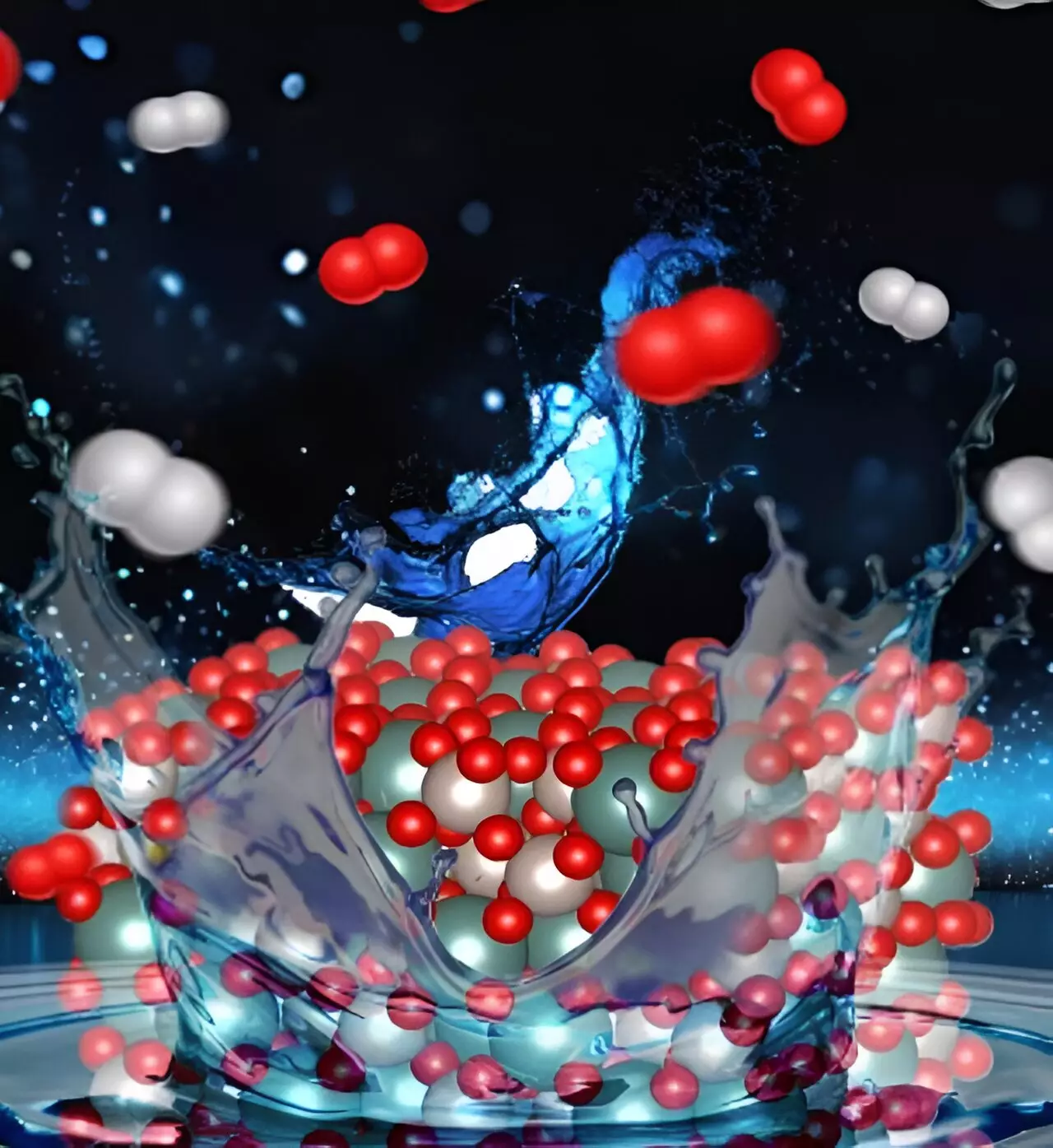

Traditional methods for producing hydrogen involve electrochemical reactions that split water molecules into hydrogen and oxygen. Commonly utilized in proton exchange membrane electrolyzers, the process demands significant efficiency to meet industrial-scale demands. While hydrogen can be produced swiftly, the simultaneous generation of oxygen proves to be a bottleneck, slowing down the overall reaction process. This imbalance restricts both the flow of electrical current and the rate of hydrogen production, presenting a significant hurdle that needs to be surmounted to enable widespread adoption of green hydrogen technologies.

Innovative Solutions: Enter Defect Engineering

A groundbreaking study published in the Journal of the American Chemical Society sheds light on an innovative technique called “defect engineering,” which can enhance catalytic efficiency in hydrogen production. An interdisciplinary research team led by Professor Hong Yang has identified a method to manipulate the electronic structure of materials to yield more effective catalysts. The study leveraged ruthenium, a precious metal, to develop a new complex oxide that serves as a potent electrocatalyst for generating oxygen. The researchers pioneered an approach wherein they introduced yttrium, resulting in a more efficient mechanism that benefits hydrogen production.

This concept may sound intricate, yet its implications are indispensable. By creating a less-than-perfect catalyst—a material embedded with “defects”—the performance can be markedly improved. This is analogous to advancements in the semiconductor industry, where introducing impurities into silicon enhances its functionality. The insights from this study illuminate a previously under-explored avenue for optimizing electrocatalysts, laying the groundwork for future breakthroughs in energy technologies.

Insights from the Research

The research culminated in the revelation that the introduction of yttrium at specific ratios can dramatically boost oxygen production activity, a critical factor in the overall hydrogen generation process. The team employed thermogravimetric analysis to evaluate the generation of oxygen vacancies within their electrocatalysts and its effects on stability and reactivity. Surprisingly, the manipulation did not alter the quantitative amount of oxygen; rather, it modified the oxidation states of ruthenium, which can lead to enhanced reactivity. This finding challenges traditional assumptions that more oxygen concentration directly correlates with better performance, offering a new perspective on catalyst optimization.

Bidipta Ghosh, a graduate engineering student and the paper’s leading author, also highlighted the importance of precisely controlling the level of defects to achieve maximum efficacy. This meticulous approach underscores the notion that not all imperfections are detrimental; rather, they can be strategically leveraged for enhanced performance.

The Importance of Collaborative Expertise

An invaluable takeaway from this research is the significance of interdisciplinary collaboration. The combination of diverse expertise allowed the team to tackle complex technical challenges in characterization and analytic methodologies. As Yang noted, this collaborative spirit was crucial in unraveling the multifaceted nature of electrocatalyst performance, reinforcing the idea that innovation thrives in environments that encourage cross-disciplinary dialogue and shared ingenuity.

Looking Ahead: The Road to Sustainable Hydrogen Production

This study’s findings are not merely incremental steps; they represent a pivotal shift that may catalyze broader advancements in green hydrogen technology. With improved electrocatalysts, the pace of hydrogen production can accelerate, heralding a new era for energy storage and conversion systems. By addressing the challenges associated with oxygen generation in electrochemical reactions and creating more effective catalysts, researchers can advance the viability of green hydrogen as a mainstream energy source.

Navigating the transition to a green hydrogen economy may appear daunting, but the potential rewards are immense. As advancements continue to refine and optimize hydrogen production, societies around the globe can move closer to realizing a future dominated by sustainable energy, significantly reducing carbon footprints and advancing the global energy landscape toward a greener future. The innovative strategies outlined in this research provide a clear path forward—one marked by creativity, collaboration, and an unwavering commitment to sustainability.