The demand for rare-earth elements (REEs) has skyrocketed in recent years as industries pivot toward green technologies. These critical materials, including neodymium (Nd) and dysprosium (Dy), are fundamental for the production of high-performance magnets utilized in applications ranging from electric vehicles (EVs) to wind turbines. The increasing push for renewable energy sources underscores the urgency of efficient recycling processes for these scarce materials. Traditional methods have often been hampered by high energy consumption and environmental concerns, highlighting the need for innovative solutions that balance economic viability with ecological responsibility.

In a seminal study conducted by researchers at Kyoto University’s Institute of Advanced Energy, a new recycling method known as the selective extraction–evaporation–electrolysis (SEEE) process has been proposed. This innovative approach stands in stark contrast to existing hydrometallurgical techniques that are frequently criticized for their complexity and energy demands. The SEEE process promises to enhance recycling efficiency while minimizing its environmental footprint—a crucial factor in the age of climate change.

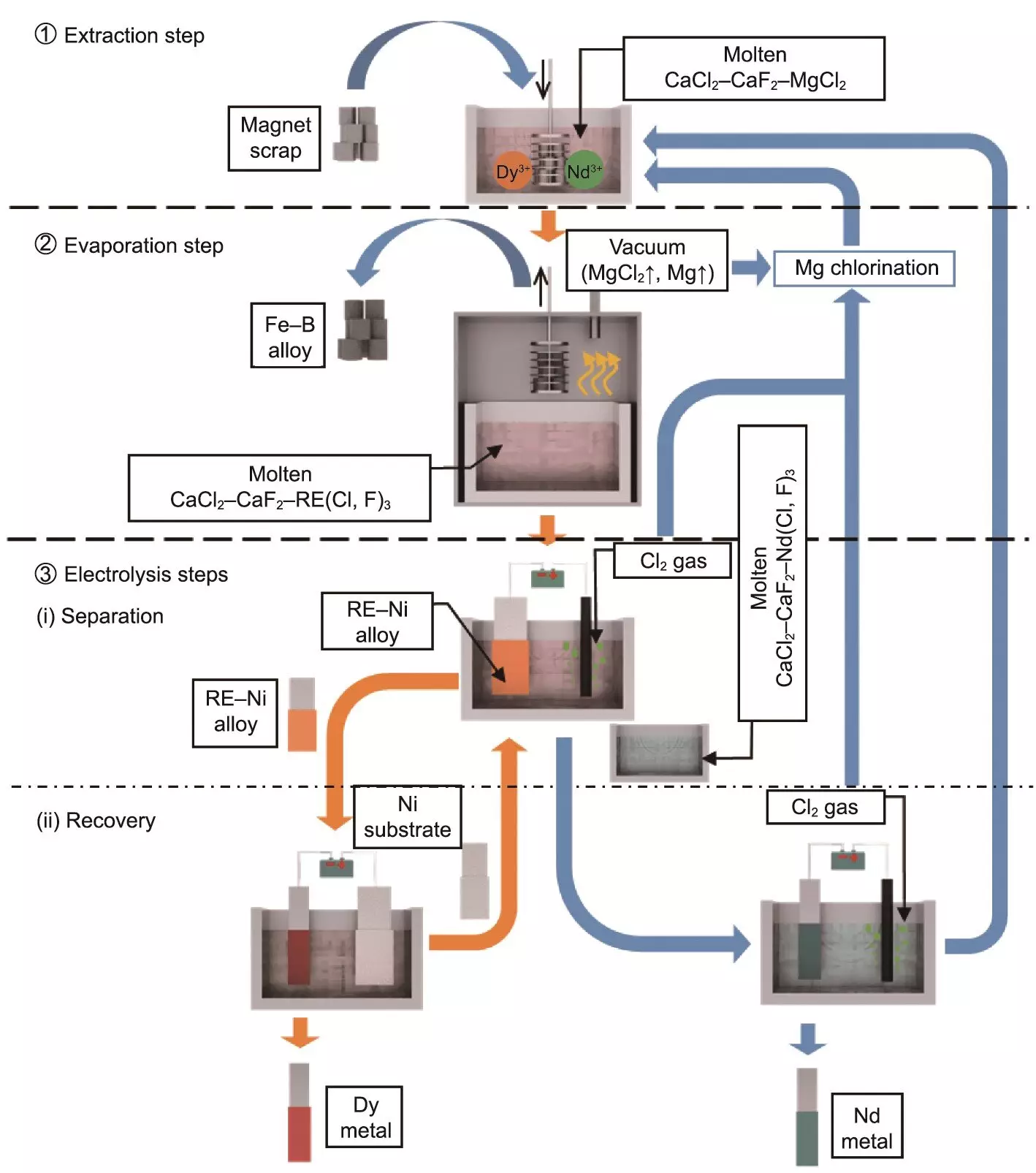

The SEEE process unfolds in three distinguishable phases that collectively optimize the extraction of REEs from end-of-life magnet scraps. The first phase involves selective extraction using a unique molten salt mixture, predominantly comprising calcium chloride (CaCl2) and magnesium chloride (MgCl2). This phase also involves the addition of calcium fluoride (CaF2) to refine the extraction yield by controlling evaporation losses. This careful design is crucial for maximizing the recovery rates of Nd and Dy from recycled materials.

The second phase, selective evaporation, focuses on eliminating residual extraction agents and other byproducts, effectively refining the concentration of REEs. The final phase, selective electrolysis, separates the REEs electrochemically based on their distinct formation potentials, ultimately enabling the recovery of high-purity neodymium and dysprosium metals.

The outcomes of this study are not only favorable but striking. The SEEE process has demonstrated recovery rates of 96% for neodymium and 91% for dysprosium, with purities exceeding 90% for both elements. Such impressive efficiency indicates both a technological and environmental breakthrough that can reshape the landscape of REE recycling. These results reveal the potential for significant reductions in the reliance on raw material extraction—a critical consideration given the social and ecological ramifications of mining activities.

As the global economy increasingly leans on electric vehicles and renewable energy technologies, reliably supplying REEs becomes ever more paramount. The SEEE process stands to revolutionize the industry by ensuring a sustainable and abundant source of these essential materials, effectively mitigating the risks associated with conventional mining methods, which often carry hefty environmental costs.

The SEEE process is not limited to the realm of recycling Nd magnets. Researchers at Kyoto University suggest that its principles can be transferred to various applications, including the reprocessing of nuclear fuels. This versatility opens a new chapter in materials engineering, broadening the scope of where such advanced recycling techniques could be applied.

While the study demonstrates considerable promise, the researchers caution that additional technical investigations will be necessary to fully transition the SEEE process into industrial applications. Nonetheless, the initial findings provide a compelling case for further development and implementation of this innovative method.

As the world grapples with the challenges of climate change and resource scarcity, the role of advanced research in crafting sustainable solutions cannot be overstated. The SEEE process represents a significant step forward in addressing the pressing issue of REE recycling while aligning with global environmental objectives. With continuous innovation, such breakthroughs will be crucial as societies transition toward carbon-neutral technologies, underscoring the imperative for efficiency, sustainability, and responsibility in resource management. Innovations like the SEEE method not only pave the way for a more sustainable future but also reaffirm the importance of scientific exploration in solving contemporary challenges.