The exploration of biological systems has captivated scientists and engineers, revealing profound insights into how nature crafts resilient structures that excel under stress. One striking example of this is the sea sponge, which adeptly combines mineral-rich layers with soft components to create an optimally balanced material. The research of Nancy Sottos, a leading materials scientist at the University of Illinois Urbana-Champaign, has significantly contributed to understanding how these natural structures can inspire the development of synthetic materials. This exploration not only emphasizes the ingenious designs found in nature but also the potential for these concepts to revolutionize modern manufacturing processes.

The intricate layering and patterning of biological materials exemplify a stimulating approach to material science. Sottos’s observations highlight a crucial notion: “Nature has a tendency to transform rigid materials into resilient ones through elaborate structuring.” This characteristic is paramount for ensuring that derived materials can endure substantial strains while also maintaining a degree of strength that prevents rupture. The research underscores an urgent need for the development of synthetic materials that mirror these naturally occurring properties to enhance their applications across various fields, from aerospace to biomedical devices.

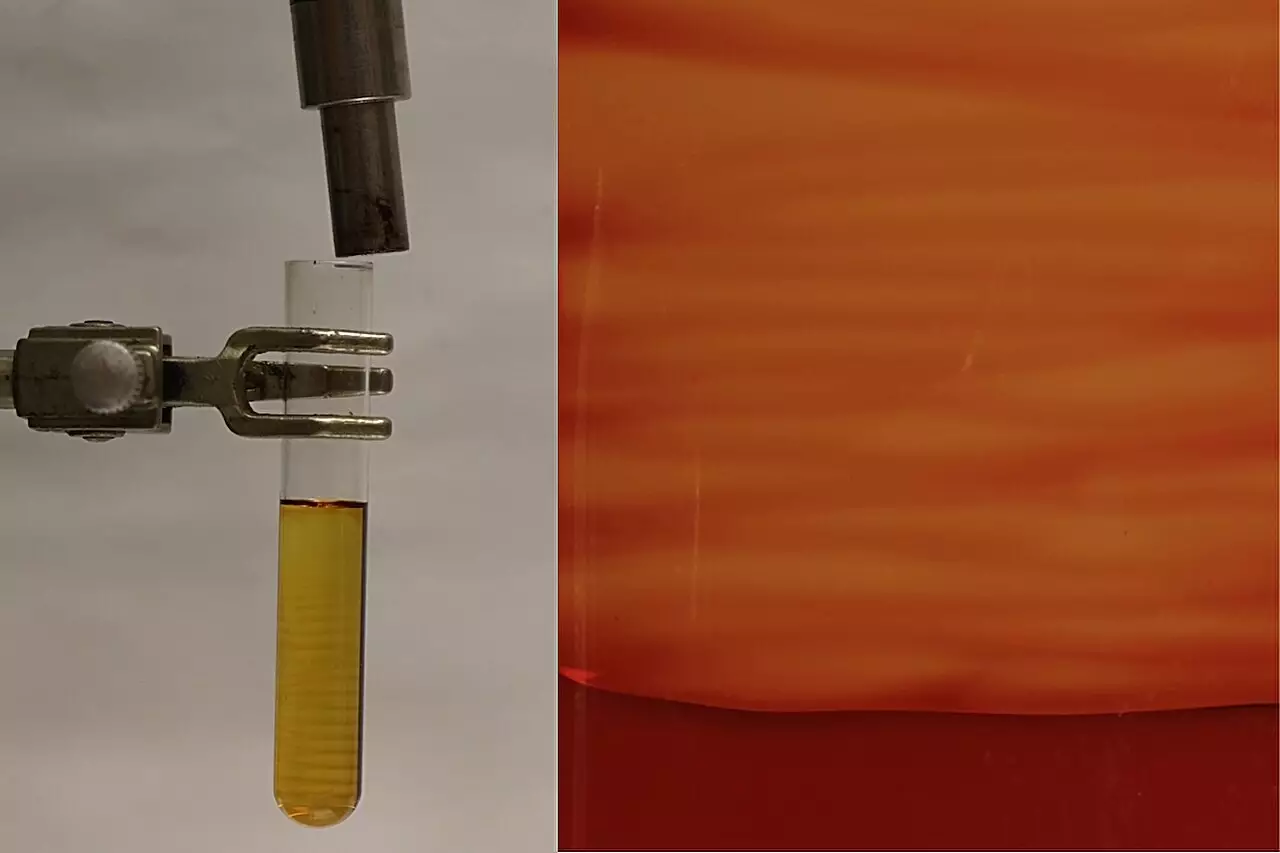

A groundbreaking study published in *Nature* emphasizes how Sottos and her team have leveraged frontal polymerization to emulate natural design principles. Frontal polymerization is an innovative method that uses heat to instigate chemical reactions, thereby facilitating the synthesis of polymers with desired properties. In a previous investigation, this team demonstrated the efficacy of this technique in producing materials inspired by biological constructs. Their current research represents a leap forward by enabling the deliberate formation of crystalline patterns within these polymers, culminating in materials with enhanced toughness and durability.

Lead researcher Justine Paul reflects on the experimental journey: “Identifying the optimal reaction conditions proved time-consuming, yet the eventual observation of dynamic spin-mode mechanics resulting in extraordinary microstructural changes was immensely rewarding.” The exploration of this interplay between various material phases—specifically, the contrast between amorphous (unstructured) and crystalline regions—illustrates a pivotal advancement in achieving resilience in synthetic materials. This nuanced design approach could transform how materials are engineered for practical applications, addressing vulnerabilities that often plague traditional methods.

The development of these novel patterning techniques was a product of extensive interdisciplinary collaborations at the Beckman Institute. Cecilia Leal’s utilization of X-ray scattering offered invaluable insights into the orientation of polymer chains within the structured material, illustrating how detailed analyses are foundational to understanding the relationships between molecular arrangements and macroscopic properties. Meanwhile, Philippe Geubelle’s contributions emphasized the significance of modeling in capturing the nuances of thermo-chemical instabilities, which are critical in forming heterogeneous materials.

Geubelle noted, “Our initiatives were greatly enhanced by collaboration across various disciplines, including mechanics, materials science, and chemistry.” These partnerships not only foster innovation but also create a dynamic environment conducive to transforming theoretical understanding into practical applications. The collaborative network at the Beckman Institute is a testament to how pooling different areas of expertise can culminate in groundbreaking advancements.

As an outcome of this innovative study, new methodologies for controlling the architecture of polymer materials are emerging. The implications of this research extend far beyond academic curiosity; they may lead to significant advancements in industries reliant on advanced materials. From enhancing the durability of protective gear to pioneering new biodegradable plastics, the potential applications are extensive.

As highlighted by Sottos and her colleagues, mimicking nature’s ability to ingeniously structure materials will pave the way for the next generation of synthetic designs. This ongoing research effort emphasizes the importance of looking to biological systems for inspiration, indicating that the fusion of technological approaches with natural wisdom could indeed yield transformative results in the realm of material science. The quest to create resilient, high-performance materials continues, driven by the remarkable insights gleaned from nature’s own designs.