The quest for sustainable materials has taken a significant leap forward, thanks to a team of bioengineers at the University of California, Berkeley. Their recent study, highlighted in the prestigious journal Science, introduces a groundbreaking environmentally friendly adhesive polymer. This inventive research not only addresses the acute need for less toxic and more sustainable materials but also showcases a promising shift in adhesive technology that could have far-reaching impacts across various industries.

Traditionally, adhesives have been characterized by their specificity; designed for particular applications such as wood bonding or metal joining, these substances often lack versatility. A significant downfall of conventional adhesives is their environmental impact, posing hazards to both ecosystems and living organisms. Zhibin Guan, a chemist from the University of California, Irvine, underscores these concerns in his Perspective article within the same issue of Science, illustrating the pressing need for adhesives that not only perform well but are also safe for the planet.

The research team’s innovative approach focused on a naturally occurring compound, α-lipoic acid (αLA), known for its inherent biodegradability. By employing an electrophilic stabilizer, they successfully moderated the breakdown process of this fatty acid, paving the way for a plethora of new adhesive products. What sets these adhesives apart is that they are not only sourced sustainably but were intentionally designed for easy degradation, minimizing their environmental footprint once their useful life has ended.

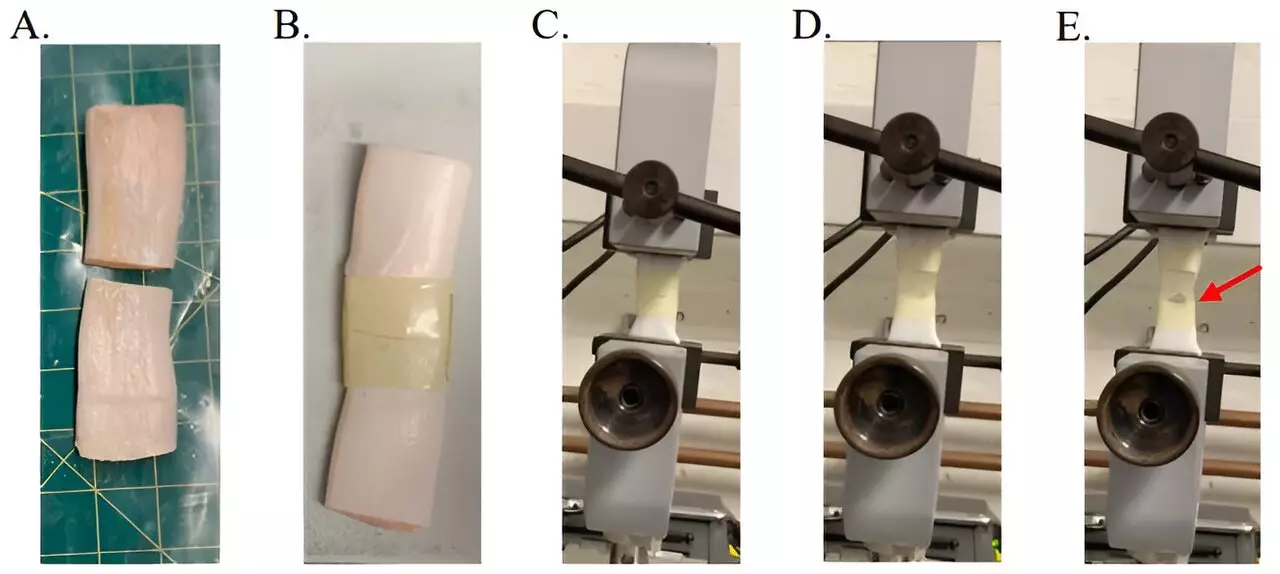

Promising results emerged from their extensive testing, which indicated that the αLA-based adhesives exhibit exceptional performance across diverse materials including wood, metal, and biological tissues. Notably, one variant of their pressure-sensitive adhesive demonstrated tenfold the peel strength compared to conventional options, affirming that sustainability does not compromise efficacy. Furthermore, these adhesives proved effective in both humid and dry environments, expanding their potential applications significantly.

A particularly intriguing characteristic of these bioengineered adhesives is their self-healing capability, an attribute that renders them especially valuable in the medical field. Such properties are critical in developing materials intended for use in surgical procedures or wound healing, where resilience and adaptability are vital. The implications of these medical applications could redefine standards for safe and effective adhesive use within healthcare.

In an impressive symbiosis of sustainability and innovation, the research team also introduced a closed-loop recycling system. This method allows for the regeneration of old adhesives into new forms by simply introducing an aqueous medium, promoting a circular economy approach in adhesive manufacturing. This system not only reduces waste but also enhances the lifecycle of materials, setting a benchmark for future research in eco-friendly adhesive technologies.

The work being done at UC Berkeley represents a significant milestone towards the development of safe, effective, and environmentally responsible adhesive solutions. These advancements challenge the conventional norms of adhesive manufacture, ushering in a new era of sustainability that other sectors might well follow. As society increasingly gravitates towards eco-conscious choices, these novel adhesive formulations have the potential to redefine industry standards while leading the charge towards a greener future.