In a world increasingly influenced by the urgent need for sustainable practices, a collaborative research effort has yielded promising advancements in battery technology. A team from POSTECH, in partnership with Hansol Chemical, has developed a groundbreaking fluorine-free binder and electrolyte system aimed at addressing both environmental concerns and the demand for high-performance batteries. Their findings, recently published in the esteemed Chemical Engineering Journal, signify not just a step forward but a pivotal shift in the materials used in lithium-ion batteries.

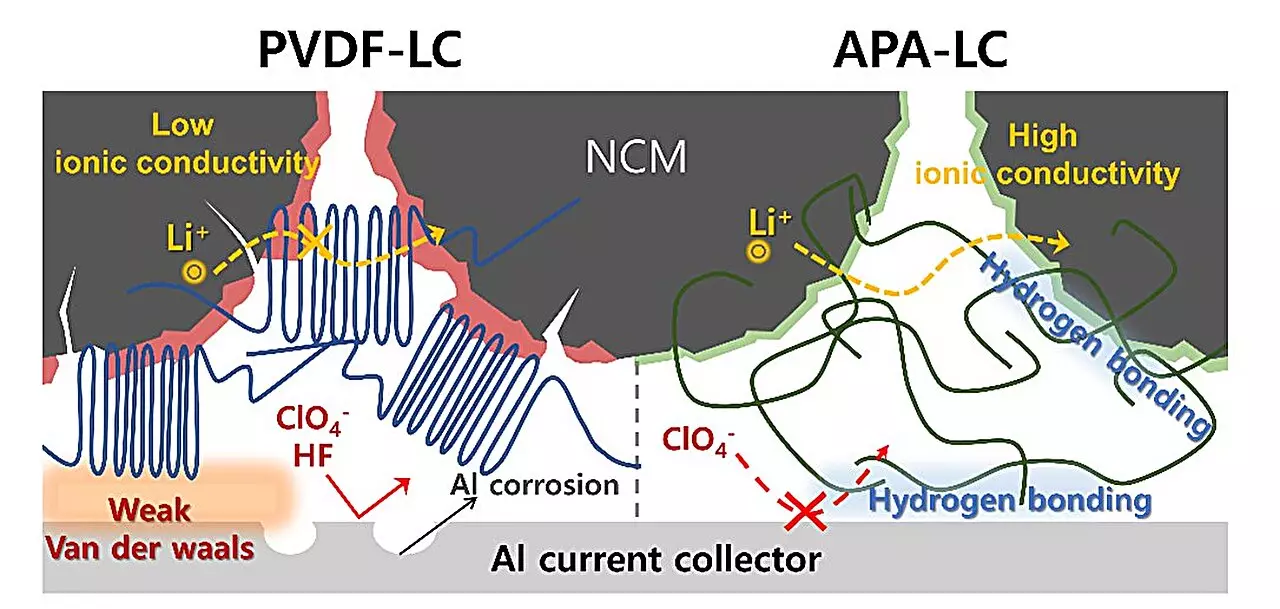

Electrochemical energy storage systems, particularly lithium batteries, have become indispensable in various applications ranging from consumer electronics to electric vehicles. However, there is a significant downside to conventional battery components. Traditional systems rely heavily on fluorinated compounds, such as polyvinylidene fluoride (PVDF) as binders and lithium hexafluorophosphate (LiPF6) as electrolytes. One critical issue with these materials is the toxic byproduct—hydrogen fluoride (HF)—that is released during battery operation, which not only endangers environmental safety but also detrimentally affects the battery’s performance and longevity.

Moreover, the persistence of PVDF in the environment raises serious concerns, particularly as regulatory frameworks, such as those from the European Union, move towards banning per- and polyfluoroalkyl substances (PFAS) by 2026. These regulations necessitate the pursuit of alternative materials devoid of harmful fluorinated compounds.

In response to these mounting pressures, the research team innovated a fully fluorine-free battery system known as the APA-LC system. This new electrical architecture replaces the conventional fluorinated electrolytes with a lithium perchlorate (LiClO4) based electrolyte, thus sidestepping the substantial risks associated with the traditional PVDF-LP systems. Furthermore, the introduction of a non-fluorinated aromatic polyamide (APA) binder enhances the critical bonding between the cathode’s active material and the aluminum current collector. This structural reinforcement is pivotal as it mitigates corrosion and significantly prolongs the overall life of the battery.

The research demonstrates that this APA-LC system not only addresses regulatory concerns but also enhances battery performance. The improved formulation comprises lithium chloride (LiCl) and lithium oxide (Li2O), which effectively reduces energy barriers at the electrolyte interface, facilitating faster lithium ion movement—an essential factor for achieving high-output performance.

The rigorous testing of the APA-LC system revealed impressive outcomes. Compared to its fluorinated predecessors, it exhibited higher oxidation stability and maintained a remarkable 20% better capacity retention after 200 cycles at a rapid discharge rate of 1C. Tests conducted within the voltage range of 2.8–4.3 V showcased the significant advantages of this new formulation. Additionally, the team successfully produced a high-capacity 1.5 Ah pouch cell utilizing the APA-LC system, which demonstrated excellent discharge capabilities during fast-charging procedures.

These achievements mark a significant milestone in the development of a fully scalable battery technology that eschews any reliance on fluorinated materials. Professor Soojin Park emphasizes the impact of these findings, noting, “We haven’t just replaced fluorinated systems; we’ve proven high-capacity retention and outstanding stability”—a testament to the robustness and viability of this new battery technology.

As the transition to sustainable battery technologies accelerates, industry stakeholders stand to gain significantly from these innovations. Managing Director Young-Ho Yoon of Hansol Chemical outlines the strategic advantage gained by complying with emerging PFAS regulations, highlighting the immense potential of the global cathode binder market, which is projected to reach KRW 1.7 trillion by 2026.

The collaborative research led by Professor Soojin Park and Seoha Nam is poised not only to disrupt established norms in the battery industry but also to position Hansol Chemical and POSTECH at the forefront of eco-friendly secondary battery material development.

The development of the APA-LC system is a landmark achievement in sustainable battery technology, presenting a viable alternative that promises to meet upcoming regulatory demands while enhancing performance and safety. As the global market shifts towards greener solutions, innovations like these will play a crucial role in shaping the future of energy storage. The relentless pursuit of eco-friendly materials in battery technology not only underscores the importance of environmental responsibility but also heralds a new age of energy solutions that don’t compromise on efficiency or performance.