Electronic waste, or e-waste, has emerged as a significant environmental challenge in recent years. As technology advances rapidly, millions of tons of outdated gadgets and devices are discarded annually, leading to a colossal waste management issue. Traditional recycling methods for recovering precious metals from e-waste often involve harsh chemicals, energy-intensive processes, and result in harmful byproducts, further exacerbating environmental concerns. Addressing this pressing issue, a research team from Rice University, led by chemist James Tour, has developed an innovative method that promises to enhance the recycling of critical metals while minimizing ecological harm.

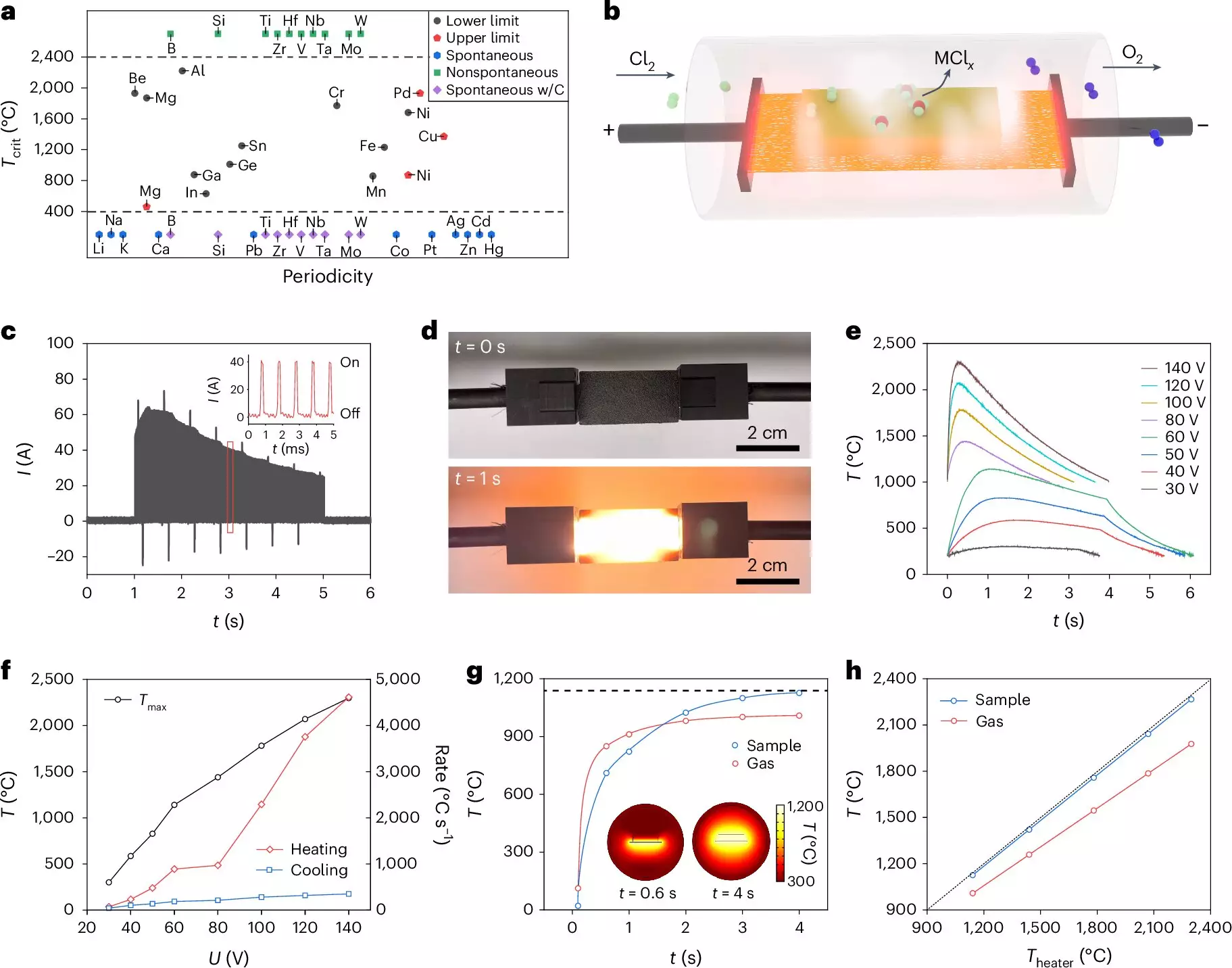

The groundbreaking technique, published in Nature Chemical Engineering, leverages a process known as flash Joule heating (FJH). This method involves subjecting electronic materials to an electric current that rapidly raises their temperature, transforming them into different compounds. By integrating chlorination techniques into their process, Tour’s team has managed to extract valuable elements like gallium, indium, and tantalum from e-waste with unprecedented efficiency. Unlike conventional recycling methods such as hydrometallurgy and pyrometallurgy, which are laborious and environmentally taxing, this new approach ensures a cleaner, more controlled environment for metal separation that drastically reduces the need for acids, solvents, and significant energy consumption.

Positive Environmental Impact

The environmental implications of this new recycling technique are profound. Current e-waste recycling methods frequently entail substantial carbon footprints, primarily due to the energy used and the toxic waste generated. By contrast, the novel method developed by Tour and his team not only lowers operational costs but also dramatically cuts down greenhouse gas emissions. This innovation serves as a crucial step in the sustainable recycling movement, reducing the demand for mining operations that contribute to deforestation, water pollution, and the release of harmful gases. As reported by Shichen Xu, one of the co-first authors on the study, this method addresses critical metal shortages while fostering a more sustainable economic model in the recycling industry.

The versatility of this new recycling approach extends beyond just a few metals. The team’s research indicates the potential for extracting additional valuable substances, such as lithium and rare Earth elements, which are essential for various advanced technologies. Former Rice postdoctoral student, Bing Deng, who contributed significantly to the research, stated that there are ongoing efforts to adapt this system for an even broader range of critical metals from existing waste streams. The capacity to achieve over 95% purity and an 85% yield signifies a landmark advancement, potentially reshaping the future of e-waste management.

As global reliance on electronic devices continues to grow, so does the urgency to develop sustainable methods for managing e-waste. The innovative research by James Tour and his team at Rice University represents a paradigm shift in metal recovery processes. By emphasizing efficiency and reduced environmental impact, their work not only incentivizes economic improvements in recycling but also takes substantial strides towards a more sustainable future. With ongoing adaptations for other critical metals, this research could pave the way for revolutionary changes in e-waste recycling, bringing us closer to a circular economy where valuable materials are continually reused rather than discarded.