In the constantly evolving field of materials science, the pursuit of innovative solutions to conventional problems remains paramount. Among such challenges is the development of lubricants, which are typically defined by their application in reducing friction. However, the prevalent reliance on synthetic materials has raised concerns regarding sustainability and environmental impacts. Recent research spearheaded by the University of Leeds provides a promising alternative: an oil-free super-lubricant derived from potato proteins. This pioneering development not only showcases the potential for botanical sources in lubrication technologies but also marks a significant step forward in sustainable engineering practices.

The fascinating concept of super lubricity—achieving minimal friction—has long been a subject of interest among scientists. By observing natural systems, particularly the synovial fluid that facilitates movement in human joints, researchers have attempted to replicate its effective properties. The new research aligns with this biomimetic approach, encapsulating this principle in an aqueous lubricant that mirrors the lubricating characteristics observed in biology. Specifically, the innovative lubricant leverages the unique structural properties of potato protein, showcasing how nature can inspire advanced engineering solutions.

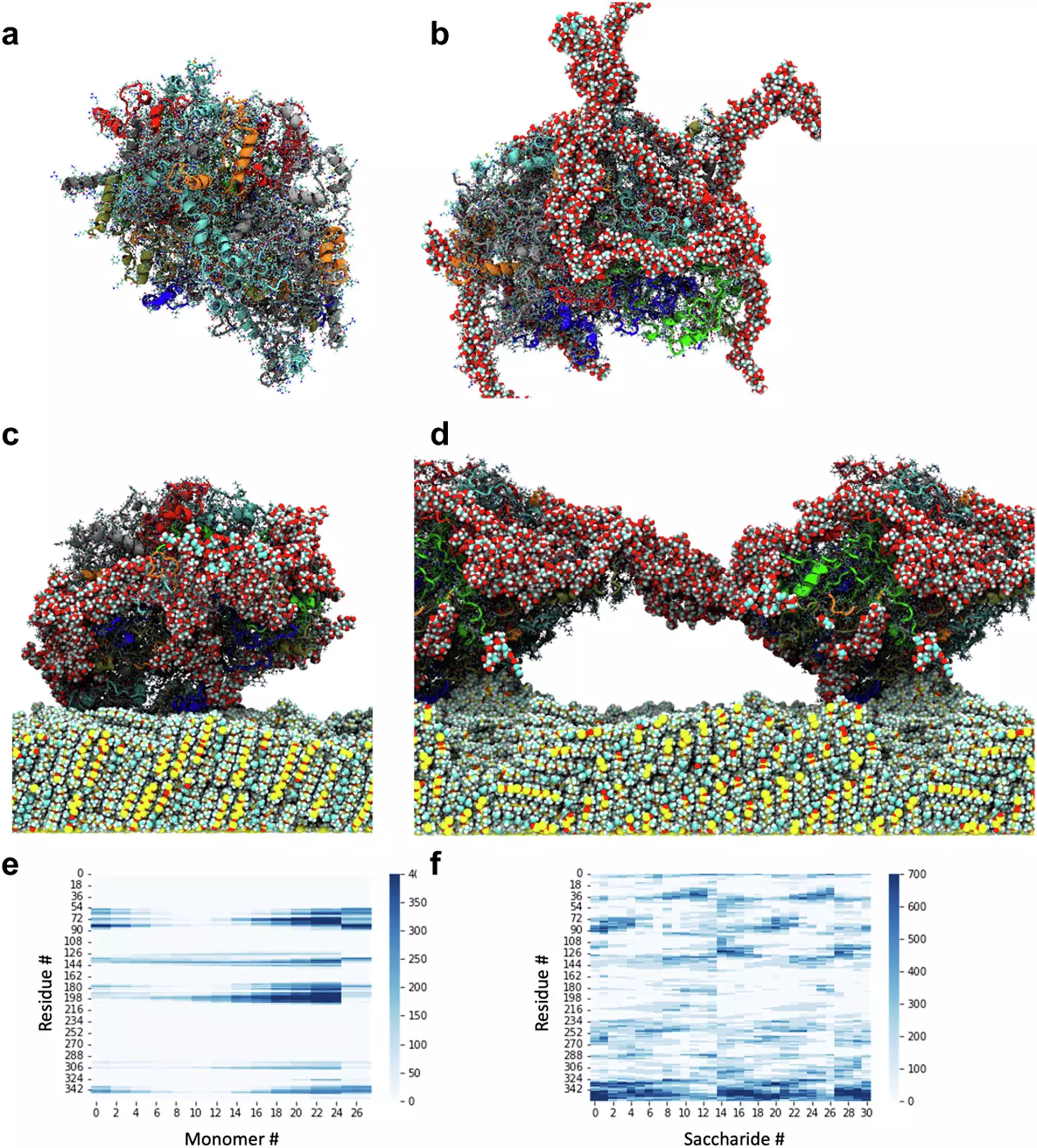

This groundbreaking study results from a collaborative effort involving experts from varied disciplines such as food science, molecular dynamics, and biophysical measurements. The diverse backgrounds of the research team—from Leeds to international institutions like the Weizmann Institute of Science in Israel and King’s College London—highlight a crucial trend in scientific research: the interdisciplinary approach. By synthesizing knowledge across multiple fields, researchers can derive more holistic solutions that encompass diverse aspects of design and function. This collaborative framework not only enhances the overall research quality but also leads to breakthroughs that might otherwise remain unachieved in isolation.

One of the standout features of the potato protein-based lubricant is its minimal carbon footprint. Traditional lubricants, often manufactured from petroleum products, contribute to environmental degradation and ecological harm. By contrast, utilizing potato protein—which can be derived from agricultural by-products—represents a resource-efficient strategy in lubricant development. Moreover, the emphasis on sustainability aligns with global trends toward eco-friendliness in engineering and manufacturing, emphasizing not only performance but also ethical production practices.

The implications of this research extend beyond traditional lubrication applications, venturing into biomedical fields and food technology. With potential uses as artificial synovial fluid, tears, and saliva substitutes, the biocompatibility of this plant-based lubricant could enhance patient outcomes in healthcare. Furthermore, the innovation’s suitability for low-calorie food production presents an intriguing avenue for culinary science, offering the potential to replicate the mouthfeel of high-fat foods without the added caloric content. Such applications resonate with contemporary dietary trends advocating for healthier consumption without compromising sensory enjoyment.

As noted by Professor Jacob Klein in the study, the research exemplifies the power of international collaboration, where the amalgamation of diverse expertise culminates in a product far superior to isolated efforts. The relationships and synergies established during this research project reflect a broader paradigm shift within academia; researchers are increasingly recognizing the need to work across borders and disciplines to address complex global challenges. This collaborative mindset is essential in advancing innovative solutions that promote sustainability.

The advent of this new eco-friendly lubricant derived from potato proteins heralds transformative possibilities in multiple scientific fields. It encourages an exploration of plant-based materials within engineering, and opens the door for future innovations that prioritize environmental sustainability. As further research progresses, the potential to fundamentally alter the landscape of lubrication technology—making it more efficient, eco-friendly, and applicable across numerous domains—becomes increasingly tangible. The findings from this study not only showcase the ingenuity present at the intersection of science and nature but also serve as an encouraging reminder that sustainable innovation is indeed within our reach.