Advancements in material science rely heavily on comprehending how microstructural characteristics affect the properties of materials. This relationship is vital for the innovation of both structural and functional materials, which have myriad applications in industries ranging from aerospace to energy. However, establishing a clear connection between these microstructural features and material performance is fraught with complexities. The challenge lies not only in the diverse nature of microstructures but also in their interactions that can lead to unpredictable material behaviors.

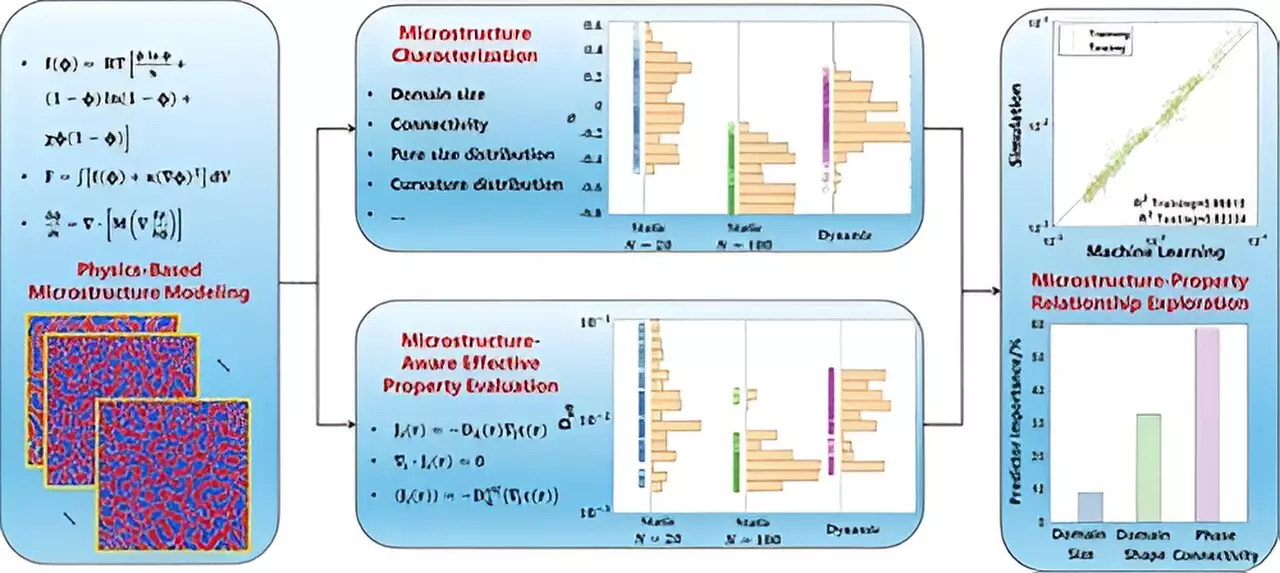

To tackle this pressing challenge, scientists at Lawrence Livermore National Laboratory (LLNL) have developed a groundbreaking computational framework aimed at illuminating the effects of porous microstructures on material properties. Their research has been documented in the peer-reviewed journal, ACS Applied Materials & Interfaces. Lead author Longsheng Feng emphasizes the significance of this framework, which incorporates a range of advanced methodologies. These include physics-driven microstructure simulations, feature extraction techniques, and machine-learning tools for property analysis.

This integrated approach allows for a nuanced understanding of how different aspects of microstructure, such as pore distribution and domain dimensions, influence the transport properties of materials. Such a holistic view is a significant leap forward from previous methodologies, which often lacked the capability to correlate microstructure features with their resulting properties effectively.

In their study, the LLNL team specifically focused on polymer-based porous materials, utilizing them as a model system to test their computational framework. This choice is compelling, as polymers are integral to various applications—ranging from biomedical devices to filtration systems. By analyzing the polymerization dynamics that affect microporous structures, the researchers were able to showcase how specific microstructural traits directly impact macroscopic material behaviors.

Co-author Tae Wook Heo highlights the framework’s dual capability: it not only aids in modeling the formation of microstructures through physics-based scenarios but also allows for effective property evaluation. This twofold approach can substantially expedite material design, enabling engineers to predict performance outcomes based on varying microstructural influences.

The insights gained from this research have the potential to revolutionize the field of material design, especially in tailoring materials for particular uses. Co-author Juergen Biener notes that a thorough understanding of the microstructure-property correlation will guide manufacturing processes to create specific microstructures that yield desired properties. This could be particularly beneficial in applications involving membranes, where precision in structural properties is crucial for performance.

Moreover, the integration of machine learning into this framework signals a shift towards more data-driven approaches in materials science. This evolution not only enhances the efficiency of material characterization processes but also paves the way for the design of next-generation materials tailored to meet specific functional requirements.

The work done by LLNL scientists represents a substantial milestone in understanding the complex interplay between microstructure and material properties. Their innovative computational framework is set to propel material design into new frontiers, enabling the development of advanced materials that meet the evolving demands of various industries. The implications of this research are vast, promising significant advancements in both theoretical and practical aspects of material science.