Engineers at the University of California San Diego have unveiled a groundbreaking 3D printing technique that simplifies the creation of solid structures using an environmentally friendly approach. This innovative method, involving a polymer ink combined with a salt water solution, was recently detailed in the prestigious journal, Nature Communications. By harnessing accessible materials and straightforward processes, the researchers aim to revolutionize materials manufacturing with sustainability in mind.

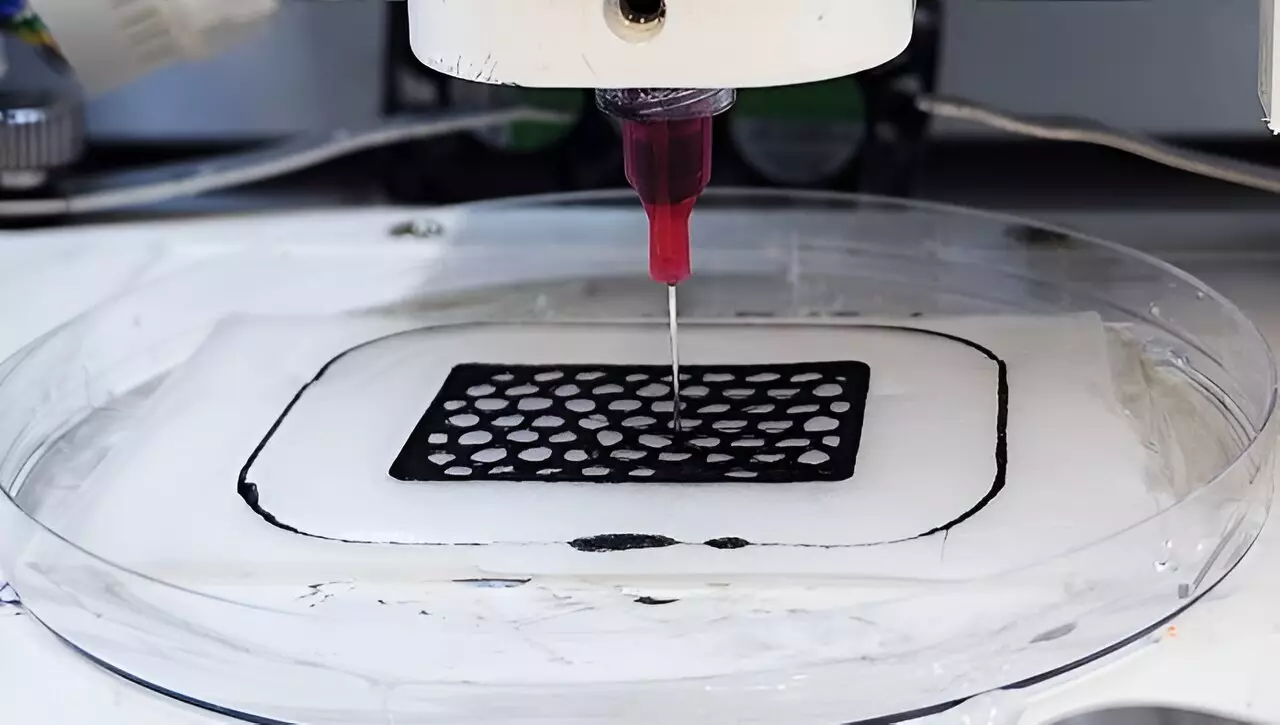

At the core of this new approach lies a unique liquid polymer solution known as poly(N-isopropylacrylamide), or PNIPAM. The process unfolds intriguingly as this polymer ink is extruded through a fine needle directly into a calcium chloride salt solution. The salient feature of this technique is its instantaneous solidification upon contact with the salt water. This rapid transformation is facilitated by the salting-out effect, where the strong attraction of salt ions to water leads to a depletion of water molecules from the polymer solution. Consequently, the polymer chains in PNIPAM become densely packed, resulting in a solidified structure. This robust method operates efficiently at room temperature without the need for energy-intensive processes or hazardous chemicals, marking a significant departure from traditional polymer manufacturing.

The implications of this new printing technique extend far beyond efficiency. Traditional polymer solidification methods often involve harmful substances and considerable energy consumption, raising serious environmental concerns. In stark contrast, this eco-friendly method relies solely on the inherent interactions between PNIPAM and salt water, dramatically reducing the environmental footprint of material production. In addition, one of the standout characteristics of the structures created through this printing process is their reversibility; these solid forms can easily dissolve in freshwater. This feature not only promotes recycling but offers an avenue for reusing the PNIPAM ink in future printing endeavors.

The versatility of this innovative method was highlighted as researchers explored the potential for incorporating various materials into their PNIPAM inks. For instance, they successfully printed an electrical circuit using PNIPAM infused with carbon nanotubes, demonstrating the practical applicability of this approach. The resulting circuit was capable of powering a light bulb and could also be dissolved in water, illustrating the potential to develop recyclable, water-soluble electronic components. Such advancements could herald a new era in the design and manufacturing of sustainable electronics.

As Jinhye Bae, the senior author of the study and a professor at UC San Diego’s Jacobs School of Engineering, articulated, this new 3D printing method represents a significant leap forward in environmentally conscious polymer manufacturing technology. By simplifying the production process and promoting the recycling of materials, this breakthrough could pave the way for sustainable innovations in various industries. The convergence of accessibility, efficiency, and environmental responsibility positions this technique as a promising candidate for the future of 3D printing and materials science. Through continued research and development, the potential applications of this technology remain vast, potentially transforming how we view and use polymers in numerous fields.