The advent of a novel microscopy technique has ushered in a transformative period for material science, unlocking the mysteries buried deep within the atomic-level architecture of crystalline substances. Researchers at the University of Sydney’s School of Aerospace, Mechanical and Mechatronic Engineering are spearheading this initiative, unveiling a mechanism to decipher intricate atomic relationships that could significantly enhance our understanding of material properties and performance. This development is not merely a technological advance; it holds the potential to catalyze a paradigm shift in various industries, including aerospace and electronics, heralding the arrival of unprecedented levels of efficiency and sustainability.

The paper recently published in Nature Materials introduces a breakthrough methodology leveraging atom probe tomography (APT), a sophisticated imaging tool that adapts to the demands of measuring short-range order (SRO). This is an exciting milestone—previously, examining atomic arrangements within materials was a laborious task fraught with challenges. Conventional microscopy techniques often fell short when it came to visualizing these diminutive structures. However, this innovative APT-based approach has broken through those barriers, promising significant ramifications across engineering disciplines.

Decoding the Material Genome

Understanding short-range order is akin to peering into the ‘material genome,’ representing the intricate layout of atoms within a crystal lattice. The arrangement, or configuration, at this micro-level influences critical physical properties, ranging from electronic conductivity to thermal stability and even mechanical resilience. With this new capability, researchers can begin to quantify how localized atomic arrangements impact a material’s overall functionality.

Professor Simon Ringer, who leads the research, emphasizes the importance of this breakthrough in shedding light on the atomic neighborhood within crystalline frameworks. No longer limited to examining the broader attributes of material structures, the focus can now shift towards the specific neighborhood arrangements that impart targeted properties like strength and durability. The implications for innovations in custom-material design are immense, as the researchers are on the brink of developing advanced alloys and semiconductor materials engineered atom by atom.

High Entropy Alloys: The Future of Engineering

The research specifically highlights high entropy alloys, which exhibit exceptional promise in various cutting-edge applications. These materials are the subject of heightened global interest, particularly for use in high-stress environments, such as aerospace propulsion systems and nuclear reactors requiring extensive protection against radiation. By harnessing the insights gleaned from this new technique, developers can refine these alloys for enhanced performance under extreme conditions, fostering advancements across multiple sectors.

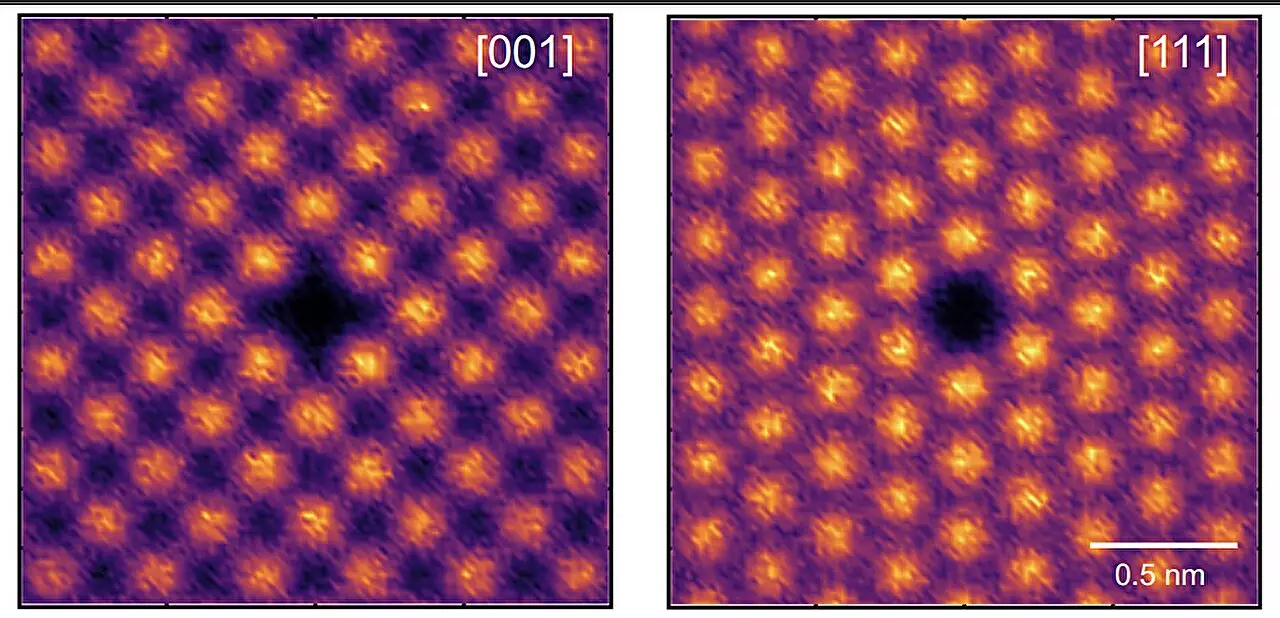

The researchers employed advanced data science methodologies informed by the insights of APT, allowing them to visualize and measure SRO in real-time. This capability transforms conventional material design—once a laborious process—into a data-driven science. By studying a cobalt-chromium-nickel high entropy alloy, the team was able to discern how various heat treatments influence SRO, further enabling fine-tuning of material properties to meet specific operational demands.

Transforming the Landscape of Materials Engineering

The significance of this research resonates through its ability to affect computational modeling in material science. Enhanced understanding of SRO lays the groundwork for more accurate simulations and predictive models, ultimately enabling engineers to anticipate material behavior under different conditions. This advancement could streamline product innovation across numerous fields, from aerospace to sustainable infrastructure, providing an invaluable toolkit for future developers.

Dr. Mengwei He, a pivotal member of the research team, articulates the transformative nature of this discovery, emphasizing how it equips material scientists with a novel perspective. Recognizing that even minute alterations at the atomic level can yield substantial improvements in material capability reframes how designers approach their work.

Additionally, the integrated methodology presents a robust framework for measuring SRO, underscoring the importance of experimental validation. Senior postdoctoral fellow Dr. Andrew Breen highlights this aspect, noting that establishing the validity of SRO measures under various circumstances enhances the reliability of the findings and deepens the knowledge pool available to engineers.

A Bright Future for Innovation

This cutting-edge research illuminates pathways towards customized, high-performance materials, presenting unprecedented opportunities for innovation. By applying the knowledge gleaned from short-range order measurements, scientists can not only engineer stronger, lighter alloys for aerospace applications but also develop next-generation semiconductors for electronics, setting the stage for improved reliability and performance across numerous technologies.

As the materials science community stands poised to capitalize on this groundbreaking work, the potential of atom probe tomography to redefine the methodologies employed in material design can’t be overstated. Ultimately, this breakthrough enhances our trajectory toward a future enriched by sustainable, efficient, and high-performing materials, promising a new archetype of engineering excellence.