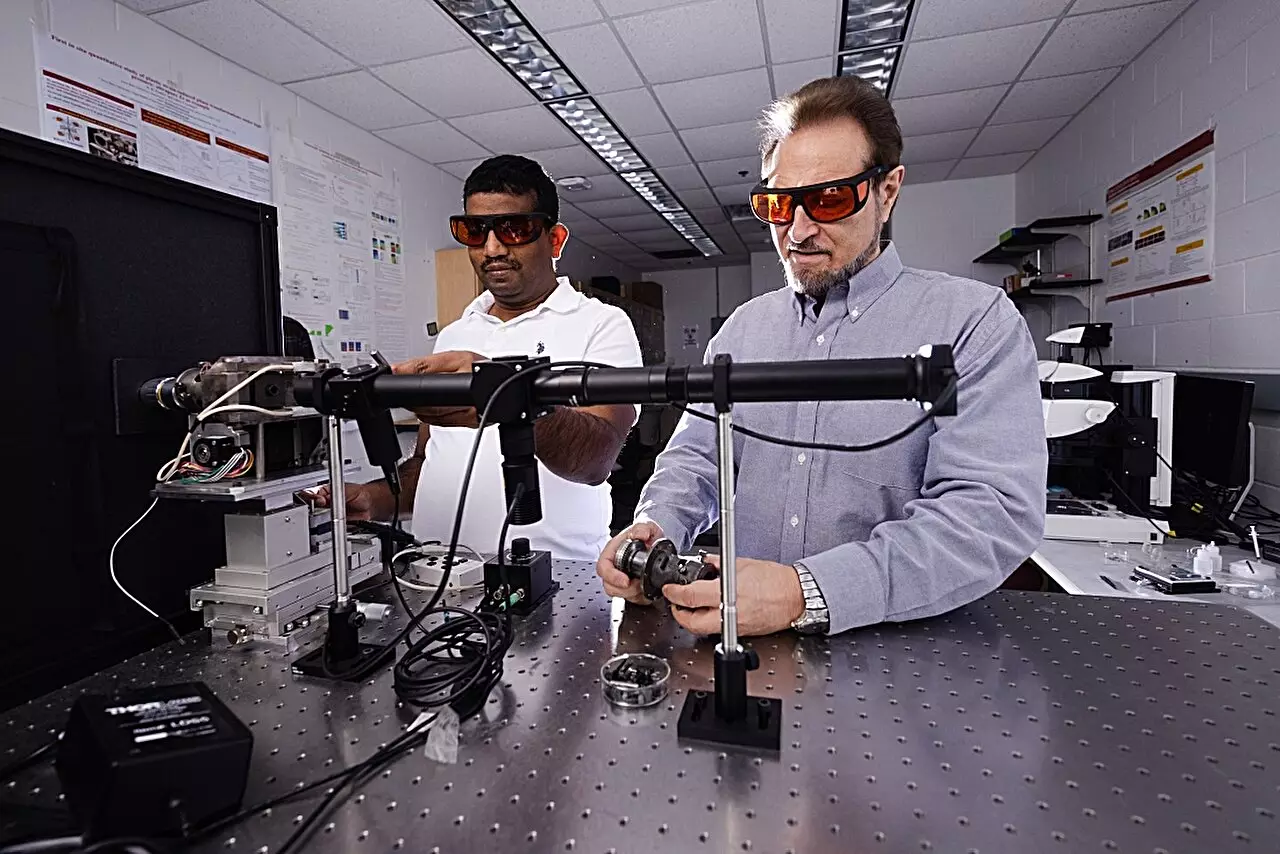

The landscape of material science is constantly evolving, fueled by innovative research methodologies and groundbreaking findings. Valery Levitas, a distinguished professor at Iowa State University, has been at the forefront of this evolution since he relocated to the U.S. from Europe in 1999. Armed with a rotational diamond anvil cell, Levitas and his team have been exploring the intricate behaviors of materials under extreme conditions. This experimental apparatus allows researchers to apply both pressure and shear to materials, enabling them to investigate their structural transformations in real-time.

These transformations have profound implications in understanding how materials behave under various mechanical stresses and could lead to the discovery of new materials with enhanced properties. Central to this research is silicon—the quintessential material for the electronics industry—which has recently yielded surprising behaviors when subjected to plastic deformation.

The research emphasizes a unique approach; rather than merely increasing pressure, it incorporates shearing forces to investigate the phase transitions of silicon. Traditional studies primarily focused on the crystallographic changes of silicon under consistent high pressure—pressures that are often impractical for industrial applications. Levitas’s group, however, delved into the realm of low-pressure transformations facilitated by shear, leading to the revelation of “plastic strain-induced phase transformations.”

Recent findings revealed that the typically stable “Si-I” phase of silicon can be transformed into the “Si-II” phase at pressures as low as 0.3 gigapascals. This finding is revolutionary compared to the 16.2 gigapascals typically required to trigger this transformation under sheer pressure alone. By reducing the pressure necessary for such transformations by a factor of 54, Levitas and his colleagues are opening new pathways for technological applications.

This pioneering research presents remarkable opportunities for various applications, particularly within the electronics industry. Each phase of silicon possesses distinct physical and electronic properties, suggesting that these transformations could yield materials that are not only stronger but also more efficient in conducting electricity and converting energy. For instance, by manipulating silicon into a nanostructured composite with optimized properties, manufacturers could harness new functionalities that would enhance device performance.

Another notable aspect of this work is the potential to create materials with ultra-thin dimensions, ranging from just 1 millionth of a meter to 100 billionths of a meter in size. At this scale, the properties of materials can be drastically different, which could revolutionize the development of next-generation electronic devices that are both lighter and more efficient.

The implications of Levitas’s findings extend beyond silicon alone; they suggest a broader potential for rethinking how materials are studied and utilized across various industries. As researchers continue to combine principles of mechanics, physics, material science, and applied mathematics, they are uncovering the complex relationships between a material’s microstructural characteristics and its macroscopic properties.

The ability to manipulate material phases at significantly lower pressures not only enhances the feasibility of industrial applications but also encourages a paradigm shift in material processing techniques. For manufacturers, this means potentially avoiding the costly and impractical high-pressure techniques traditionally associated with material transformations.

Would we not all benefit from tapping into the youthful vigor of experimentation and fresh thinking, much like Levitas and his team? As they delve deeper into the nuances of material behaviors under pressure and shear, the field of material science stands on the precipice of significant advancements, paving the way for innovations that could well redefine modern engineering standards.

Valery Levitas’s explorations into the transformations of silicon provide compelling evidence that the future of material science may lie in the delicate interplay of pressure and shear. As these new findings ripple across various sectors, they are set to influence the next wave of technological advancements in material engineering.