The need for more efficient, sustainable, and safer energy storage solutions has never been more pressing. With the increasing demand for electric vehicles (EVs) and renewable energy sources, researchers are exploring alternative technologies to complement or replace traditional lithium-ion batteries. Among the promising contenders, sodium-ion batteries are garnering attention for their potential advantages over their lithium counterparts. A groundbreaking study led by Dr. Daeho Kim and Dr. Jong Hwan Park at the Korea Electrotechnology Research Institute (KERI) introduces a revolutionary method for the preparation of hard carbon anodes in sodium-ion batteries using microwave induction heating. This innovative approach could significantly enhance the viability of sodium-ion technology.

Sodium-ion batteries utilize sodium (Na) instead of lithium (Li), making them an attractive alternative due to sodium’s abundance—over a thousand times more plentiful than lithium. Furthermore, sodium’s lower reactivity translates to enhanced electrochemical stability, allowing for quick charging and discharging without compromising performance, particularly in low-temperature environments. These inherent advantages position sodium-ion batteries as a favorable option in scenarios where safety and efficiency are paramount, such as in electric vehicles, especially highlighted by recent safety concerns over lithium battery fires.

However, despite these benefits, sodium-ion batteries face critical challenges. Their energy density does not yet match that of lithium-ion batteries, and the manufacturing processes are notably complex. The larger size of sodium ions necessitates the use of hard carbon anodes, which must be synthetically produced due to the absence of a natural counterpart. The traditional preparation of hard carbon involves a labor-intensive and high-temperature “carbonization” process which poses significant economic and environmental hurdles, hindering the widespread commercialization of sodium-ion batteries.

Microwave-Induced Innovation

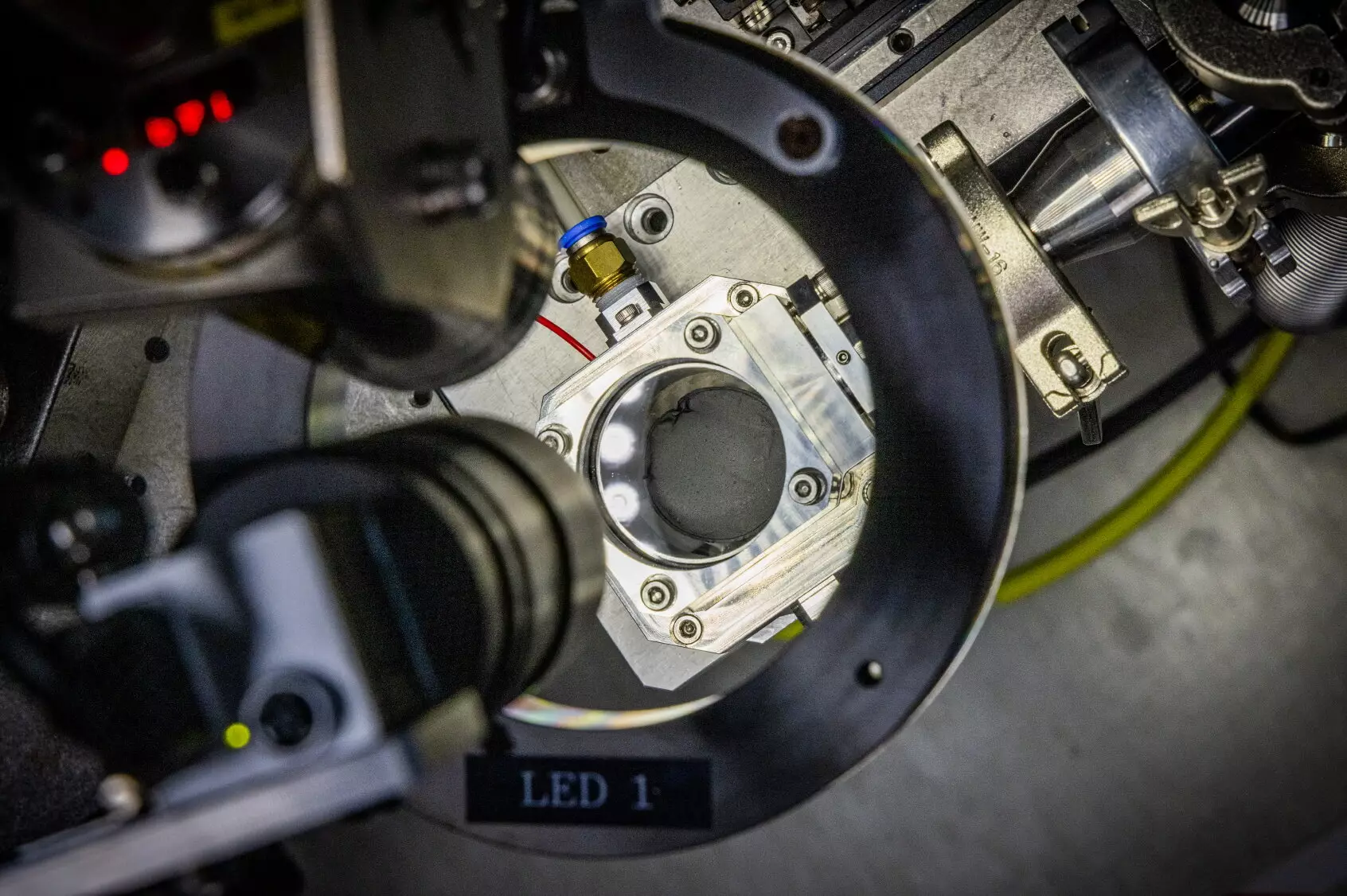

Dr. Kim and Dr. Park’s research primarily addresses these challenges with the introduction of a rapid microwave heating method that dramatically reduces preparation time. By utilizing microwave magnetic fields, the team successfully developed hard carbon anodes in merely 30 seconds. This method harnesses the principles behind microwave ovens, applying them to the synthesis of battery materials. The process begins with the creation of films made from polymer composites infused with conductive carbon nanotubes. Through the application of microwave energy, the films are heated to temperatures exceeding 1,400°C in a fraction of the time compared to traditional methods, providing a sustainable and cost-effective alternative.

This breakthrough stems from KERI’s extensive experience in the application of microwave technology across various industrial processes, particularly in areas like semiconductor manufacturing. The Nano Hybrid Technology Research Center, led by Dr. Kim and Dr. Park, stands at the forefront of this research, leveraging advanced techniques such as “multiphysics simulation.” This simulation enables a deeper understanding of the electromagnetic effects on nanomaterials, ultimately leading to the efficient design of the hard carbon anode preparation process.

The implications of this research extend far beyond sodium-ion battery anodes. Dr. Park notes that the energy efficiency of the carbonization process has historically been a hurdle, but this new technology promises a solution, potentially transforming the landscape of energy storage materials. The research findings, published in the Chemical Engineering Journal, co-authored by student researchers Geongbeom Ryoo and Jiwon Shin, highlight a collaborative effort to push the boundaries of battery technology.

Looking ahead, the research team aims to optimize the performance of their hard carbon anodes, exploring pathways for mass production and further applications in other energy storage technologies, including all-solid-state batteries requiring high-temperature processes. The versatility of microwave induction heating suggests it could revolutionize a range of industrial applications beyond the energy sector, warranting further exploration.

Commercialization and Industry Collaboration

KERI’s ongoing initiatives include securing domestic patents and fostering partnerships with industry leaders in energy storage to facilitate technology transfer. With growing interest in safer, more efficient battery technologies, the potential for sodium-ion batteries to reshape energy storage solutions is significant.

The innovative methodology developed by Dr. Daeho Kim and Dr. Jong Hwan Park opens new avenues for advancing sodium-ion battery technology. As researchers continue to explore and refine these promising techniques, the future landscape of energy storage could become marked by increased efficiency, safety, and accessibility. The work being done at KERI serves as a vital step toward realizing the full potential of sodium-ion batteries, ultimately contributing to the sustainability of our energy systems.