In the rapidly advancing field of biomedical engineering, the pursuit of innovative materials that can effectively replace or repair human tissues has emerged as a paramount challenge. Researchers are not only tasked with creating materials that mimic the mechanical properties of native tissues but also ensuring that these materials can seamlessly integrate with the human body. A collaborative team led by the University of Colorado Boulder, alongside experts from the University of Pennsylvania, has made significant strides in this area by developing a pioneering technique to 3D print highly elastic and durable biomaterials. This breakthrough, detailed in a recent issue of *Science*, marks a substantial leap towards the creation of personalized medical solutions that cater to individual patient needs.

Human tissues are often characterized by their unique combinations of strength, flexibility, and the ability to accommodate variable shapes and sizes. For instance, cardiac and cartilage tissues are notorious for their limited capacity to regenerate after injury, making the development of effective repair materials critically important. Traditional biomedical implants often fall short because they are usually mass-produced without the capacity for customization. Conventional manufacturing methods like molding and casting are inadequate for patients whose biological structures may differ significantly from typical scenarios. This is where 3D printing demonstrates its transformative potential: it allows for the creation of complex geometries and the personalization of implants.

However, 3D printing in the biomedical context is not without its challenges. Materials such as hydrogels—widely considered ideal for creating artificial tissues due to their biocompatibility and water-rich composition—have historically faced limitations. They can either lack the necessary toughness or fail to maintain elasticity when subjected to the biological forces they will encounter within the body.

Drawing inspiration from biological systems, notably the behavior of worms that exhibit remarkable abilities to fold and stretch, researchers created a new method called Continuous-curing after Light Exposure Aided by Redox initiation (CLEAR). This method facilitates the entanglement of molecular chains within the 3D-printed structures, mimicking the dynamic properties of tissues. By incorporating this entanglement, the resulting hydrogels achieved unprecedented mechanical integrity.

When tested under stress, the newly developed materials demonstrated a tenacity that was strikingly superior to traditional 3D-printed hydrogels. This advancement allows for these materials to serve not just as passive supports, but as active components that conform and adhere to various tissues, maintaining their integrity under mechanical load. In laboratory settings, team members subjected samples to various stress tests, including one dramatic instance where a bicycle was rolled over a specimen, showcasing the material’s exceptional resilience.

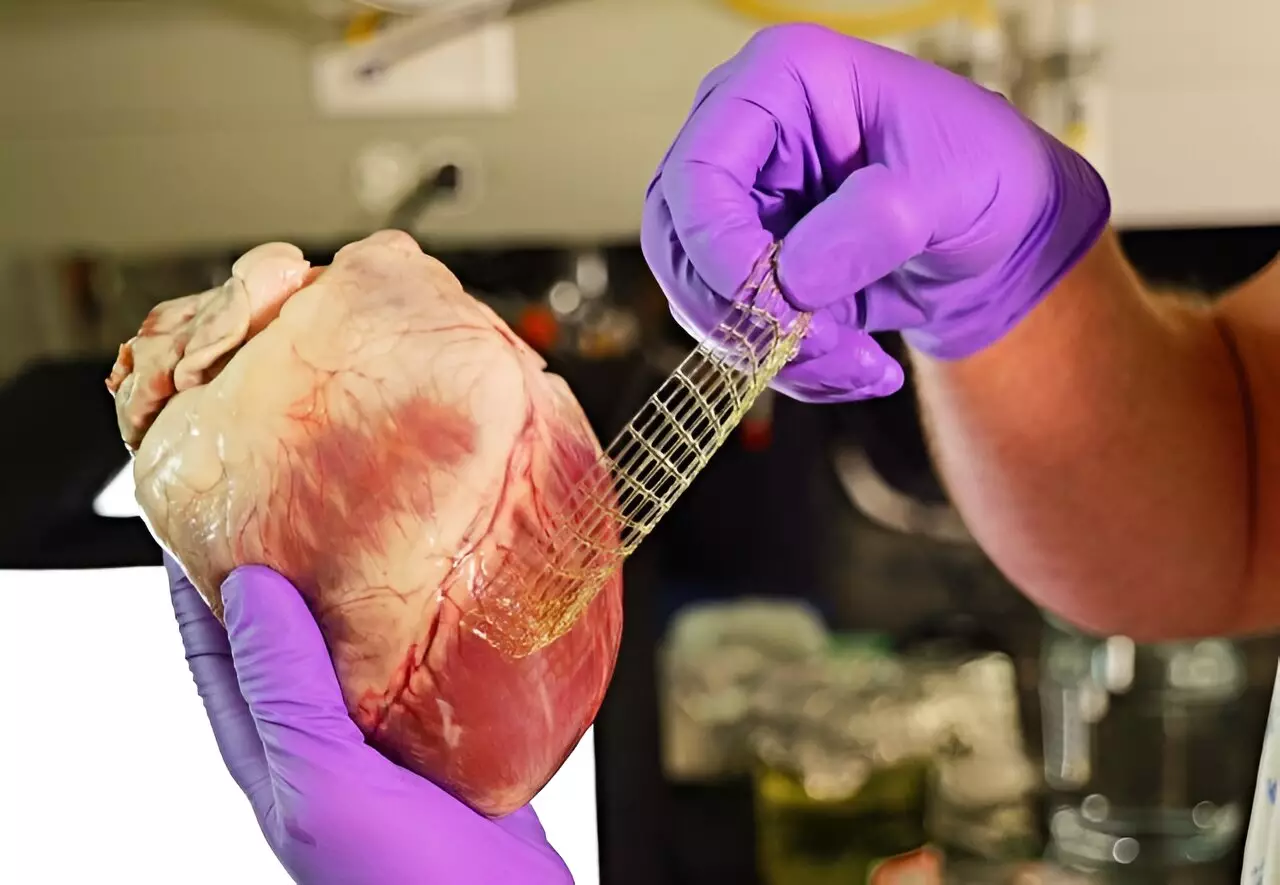

The implications of this research extend far beyond mere mechanical enhancements. The ability to create biomaterials that can conform tightly to tissues opens up a wide array of potential applications in medicine. Envision a future where damaged heart tissues receive direct therapeutic interventions through precisely designed bioactive materials, or where cartilage defects can be repaired through the deployment of customized patches that adhere seamlessly and provide functional support.

Moreover, the application of these materials could revolutionize surgical techniques. The advent of needle-free sutures could mitigate tissue damage during surgical procedures, significantly improving patient outcomes and recovery times. Researchers in Burdick’s lab are excited about the possibilities, anticipating that this technology could have profound effects on treating a variety of ailments, including advanced cardiac conditions and degenerative joint diseases.

Beyond medical applications, the CLEAR method heralds opportunities for advancements in research and manufacturing. Its energy-efficient design process could lead to more sustainable practices in material development across various industries. The team’s assertions promise that this technology will not only improve the mechanical properties of materials but also democratize the capabilities of 3D printing in laboratories worldwide.

As the researchers prepare to file for a provisional patent, they look forward to conducting further studies investigating the interactions between these innovative materials and biological tissues. This foundational step is merely the beginning of what could be a broader paradigm shift in the ways we conceive of and utilize biomaterials.

This innovative technique heralds a new era in regenerative medicine. Through meticulous research and collaboration, scientists are now paving the way for materials that not only solve current limitations but also enhance the possibilities for personalized patient care in the realm of tissue repair and beyond.