Catalysts are pivotal in numerous industrial processes that shape our daily lives. They facilitate essential reactions in the automotive sector, particularly in emissions control systems like catalytic converters, as well as within the chemical industry, where they are instrumental in producing fertilizers. The efficiency of these processes is often determined by the catalysts employed, which enhance reaction rates while minimizing energy input and unwanted byproducts.

Traditionally, catalysts have relied on rare and expensive precious metals, such as iridium and rhodium. These materials not only inflate production costs but also impose environmental burdens due to their extraction processes and long-term impacts. The pressing need for sustainable manufacturing practices has propelled researchers to seek alternatives that are both cost-effective and less harmful to the ecosystem.

As highlighted by Prof. Dr. Robert Kretschmer from Chemnitz University of Technology, substituting these precious metals with more abundant options, like aluminum and gallium, could revolutionize catalytic processes. These metals are not only cheap and non-toxic but also plentiful in the Earth’s crust and possess intriguing chemical properties. Their deployment as catalysts could significantly transform the landscape of industrial synthesis, making it greener and more sustainable.

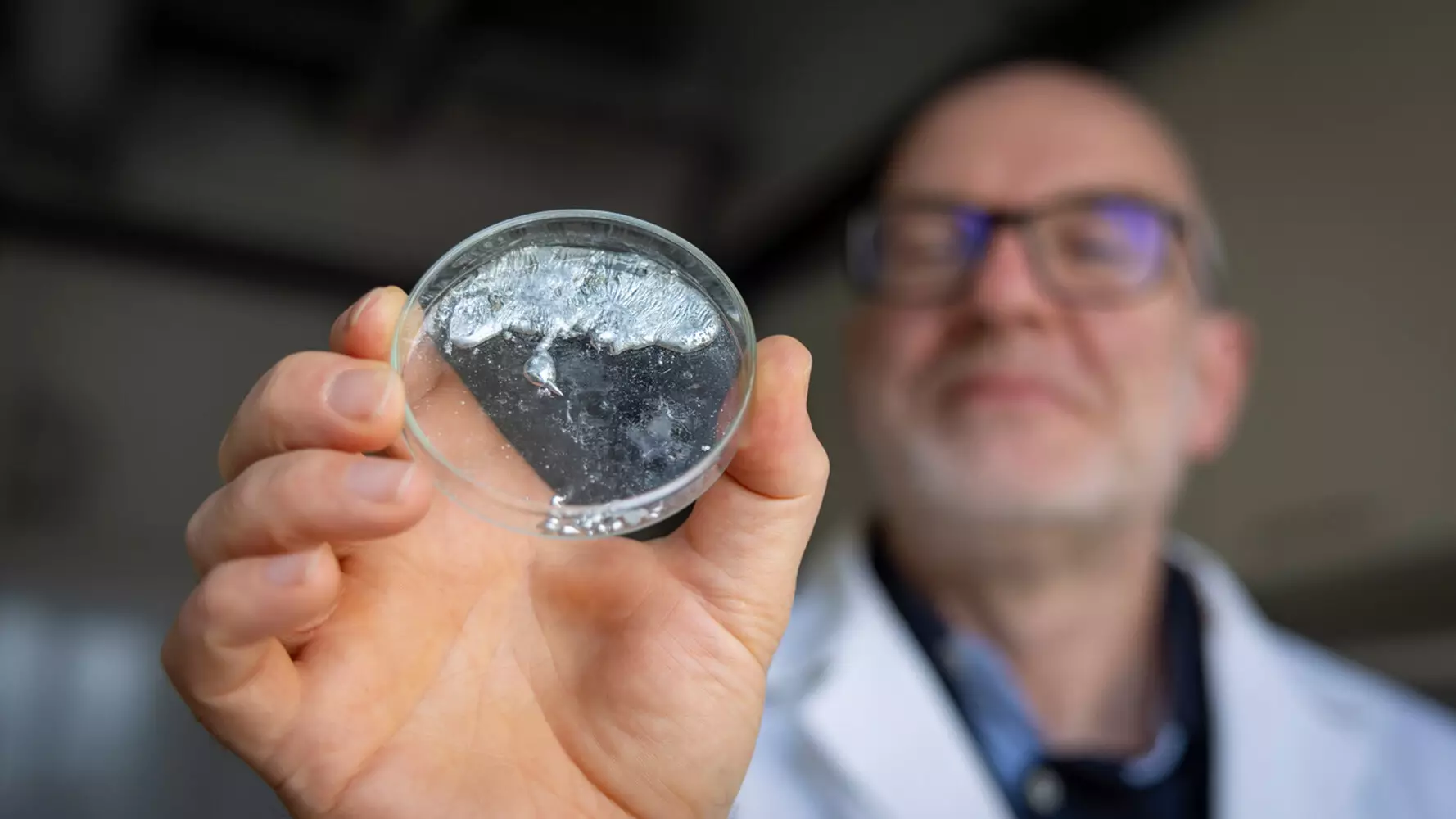

Despite the advantages of aluminum and gallium, one of the notable hurdles lies in adapting existing catalytic strategies to incorporate these elements. Kretschmer and his colleagues have made a groundbreaking discovery in this context by successfully identifying a gallium compound exhibiting reactivity previously affiliated only with its precious metal counterparts. This new compound is unique in that the gallium atom binds solely to one carbon atom, a characteristic that is rare among similar molecules.

The ramifications of this discovery extend beyond mere academic interest. The team observed an unprecedented reaction involving gallium, where it managed to generate an insertion reaction that allows the gallium to bond with two carbon atoms without increasing its bond count in the process. This innovative twist on traditional reactions could unlock new opportunities for gallium and aluminum in industrial applications, providing a pathway towards cost-effective and environmentally-friendly synthetic routes.

The findings published in the journal “Nature Synthesis” underscore a pivotal moment in chemical research. Establishing methods to utilize readily available main group metals in catalysis represents a significant advancement in striving for sustainable industrial practices. By transforming our approach to catalysts, we can not only reduce reliance on precious metals but also foster a greener and more efficient future for chemical manufacturing. As global research initiatives continue to evolve around these promising alternatives, the chemistry community may soon see a paradigm shift that prioritizes sustainability without sacrificing efficacy in production.