Traditionally, voids or pores within materials have been perceived as serious defects that compromise their mechanical integrity. Commonly found during the manufacturing process, these voids are often associated with reduced strength and increased susceptibility to failure. However, recent investigations led by Professor Jin Haijun at the Institute of Metal Research of the Chinese Academy of Sciences reveal a paradigm shift in this understanding. Far from being detrimental, the purposeful incorporation of nanoscale voids may elevate the performance of certain metals, challenging long-standing notions in material science.

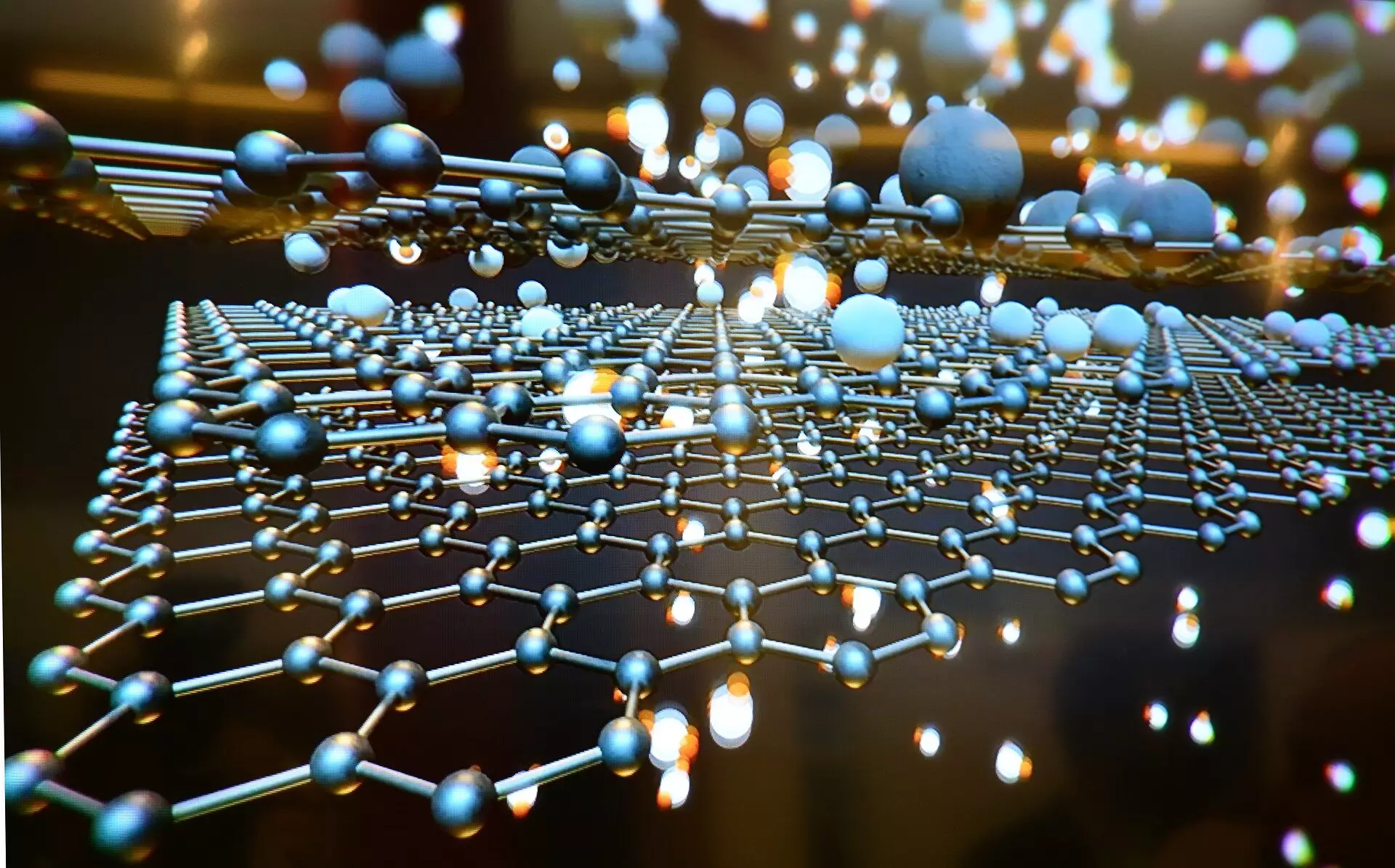

The research team, through rigorous experimentation, unveiled a novel metal composite known as nanovoid dispersed gold (NVD Au). This innovative material incorporates a multitude of nanoscale voids, ranging between a few and several hundred nanometers, uniformly distributed throughout its structure. By employing a combination of dealloying, thermal annealing, and compression techniques, NVD Au was synthesized in a manner that not only maintains but enhances the inherent properties of gold. This highlights a crucial milestone: the ability to enhance metal mechanical performance without altering its fundamental composition.

Mechanical Advancements

The results published in the journal *Science* illustrate that NVD Au exhibits significantly improved mechanical characteristics when subjected to tension, showcasing greater strength and ductility compared to traditional fully dense gold. This advancement translates into the potential for NVD Au to endure extreme loads and deformation without fracturing, providing a stark contrast to the weaknesses associated with larger voids typically produced via powder sintering or additive manufacturing methods.

The underlying mechanism of this enhancement is believed to stem from improved interactions between dislocations—imperfections within the metal’s crystal lattice—and the surface of the voids. These dislocation-surface interactions serve to impede crack formation, a critical factor in the overall durability and performance of materials.

The implications of this research extend far beyond academic interest. The ability to produce lightweight materials with exceptional strength opens up a plethora of opportunities across various industries. From portable electronics—where weight is a crucial consideration—to aerospace applications that demand resilient materials, the NVD Au innovation could redefine manufacturing standards.

As Professor Jin noted, “We achieved both NVD strengthening and density reduction simultaneously,” emphasizing that this technique preserves the essential qualities of the base material while enhancing its capabilities. Further collaborative efforts involving scientists from the Liaoning Academy of Materials and Nanjing University of Science and Technology may herald new horizons in material science, enabling engineers and manufacturers to leverage this groundbreaking approach effectively.

The discovery that nanoscale voids can be beneficial rather than detrimental marks a significant turning point in material research. By embracing the potential of these voids, scientists are paving the way for the development of stronger, lighter materials that could revolutionize the fields of engineering and manufacturing. With continued investigation into their properties and applications, nanoscale voids may well redefine our understanding of material performance for years to come.