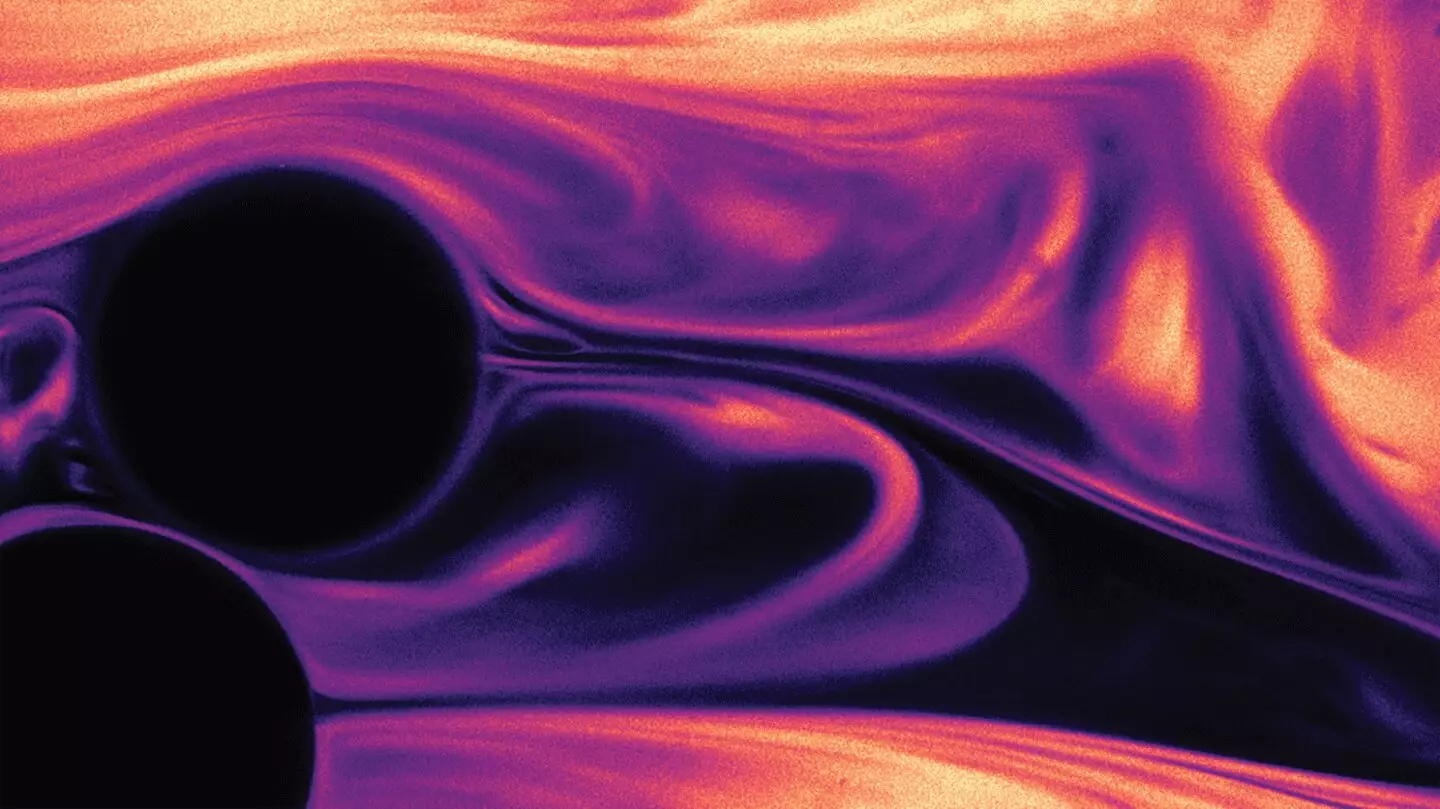

The mesmerizing sight of cream swirling into a cup of coffee brings to mind nature’s dynamics, as eddies form and dance together—an analogy reminiscent of the tumultuous storms on Jupiter. This visual charm hides a profound scientific principle that governs not just our morning brew but also various industrial processes globally. When you stir that cup, you not only achieve a deliciously blended beverage, but you also initiate a physical manifestation of fluid dynamics, which is essential for producing a myriad of products we engage with daily. The act of mixing, however trivial it may appear, has intricate implications and applications beyond the coffee shop.

Industrial Significance of Mixing

In the manufacturing sector, mixing is far from a whimsical act; it is a critical phase in producing everything from the plastics in our devices to the chemicals utilized in pharmaceuticals. Industries depend on efficient mixing processes to ensure that components blend seamlessly, allowing for optimal reactions and consistent product quality. Yet, the “coffee mug” style mixing—with its natural turbulence and large volumes—is not always applicable in industrial settings. Many processes involve substances that need their fluids to permeate through packed materials, akin to the nuanced art of brewing espresso, where small spaces are dominated by constricted flow dynamics.

This necessity poses a challenge: the tightly packed grains that enhance contact surfaces for reactions create narrow pores insufficient for the chaos and turbulence needed for effective mixing. As a result, industries have been yearning for a way to inject that much-needed turbulence back into these confined environments.

The Princeton Breakthrough

Enter the breakthrough finding from Princeton Engineering researchers, which promises to be a game changer in the field of fluid mixing. By incorporating spring-like polymers into one of the liquids in the mixture, researchers have effectively engineered a method to mimic turbulent mixing in these porous environments. This innovation is much more than a theoretical exercise; it has been shown that this technique can significantly accelerate chemical reaction rates—by as much as tenfold. This is not only an impressive number but suggests profound implications for improving industrial processes that rely heavily on mixing.

The visionary behind this research, Christopher Browne, embarked on this journey during his tenure at Princeton. What began as an exploration into mixing dynamics ultimately unfolded into an expansive investigation involving various challenges. His revelations about the properties of polymers and their roles in the movement of liquids through narrow spaces have culminated in this noteworthy development.

Bridging Gaps and Sparking Innovation

What makes this research particularly compelling is how it can potentially democratize mixing techniques across industries. For decades, scientists have attempted to alter the geometries of packed materials to enhance mixing. However, this was often met with challenges relating to cost and feasibility, especially in settings where altering the material’s configuration is impracticable. Browne and his team’s approach bypasses these expensive alternatives by utilizing commonly available polymers, allowing for a robust solution primed for diverse applications.

The polymers themselves, intriguingly, share properties with materials found in everyday products like diapers, seamlessly transitioning these components from mundane to vital in enhancing industrial efficiency. This intersection of common materials and innovative science exemplifies how practicality can spark breakthrough solutions.

A New Paradigm in Chemical Engineering

Browne, reflecting on his journey, noted that stepping back from a problem can sometimes yield clearer insights and fresh methodologies. This constructive detachment allowed him and advisor Sujit Datta to regroup and visualize their findings anew, leading to this transformative study that fuses mathematical elegance with material simplicity. Their work is not just aimed at enriching academic knowledge; it is positioned to address real-world engineering challenges—making the production of essential chemicals more efficient.

Datta himself articulated an inspiring vision for the future of this technique—claiming it as an exquisite synthesis of aesthetic and utility. Beyond showcasing advanced fluid mechanics, it presents tangible solutions to engineering dilemmas, steering us toward a future where practical mixability could redefine production methods across numerous fields.

In encapsulating the journey from a simple act of stirring a coffee cup to revolutionary industrial applications, the significance of this research transcends its immediate implications. It challenges the perception of fluid dynamics and encourages a reassessment of how we approach and innovate within the realms of material science and chemical engineering. The future of mixing promises not just to be effective but also wildly imaginative.