The quest for technological advancement has always involved an intricate dance between experimentation and understanding. Thomas Edison’s relentless pursuit of the perfect filament led him to test thousands of materials before he successfully crafted a working lightbulb. This historical pursuit is emblematic of an essential aspect of innovation: the trial-and-error method, which remains a cornerstone of contemporary research and development. Today, a parallel effort can be observed in the evolution of battery systems, integral to our daily lives in both visible and invisible ways. However, today’s engineers recognize that experimentation alone will not suffice. To foster the next generation of groundbreaking materials and devices, they must also harness a profound comprehension of the principles governing material behavior and performance.

In recent research published in the *Proceedings of the National Academy of Sciences*, a collaboration among scholars from the University of Delaware (UD), Northwestern University, and industry experts has yielded significant insights into the behavior of electrons within conductive slurries—substances pivotal to electrochemical devices like batteries. Understanding the pathways electrons traverse in these materials is crucial because their movement directly influences device efficiency. The study is notable not just for its findings, but also for the collaborative spirit fueling it. Lead authors, including notable alumni from UD and current Northwestern researchers, have combined their expertise to bridge gaps in our understanding of electrochemical performance.

One of the study’s critical revelations is the importance of microstructural influences on electrical conductivity in slurries. Norman Wagner, the lead researcher, articulates that optimizing battery performance extends beyond formulation chemistry; it necessitates a nuanced understanding of how the slurry’s microstructure is affected by manufacturing processes. This means that, similar to how a racecar’s performance relies on its design and assembly, the efficiency of an electrochemical device hinges on how its components are arranged and interconnected. Wagner emphasized the necessity of controlling both the chemistry and the physical structure during manufacturing to improve performance outcomes.

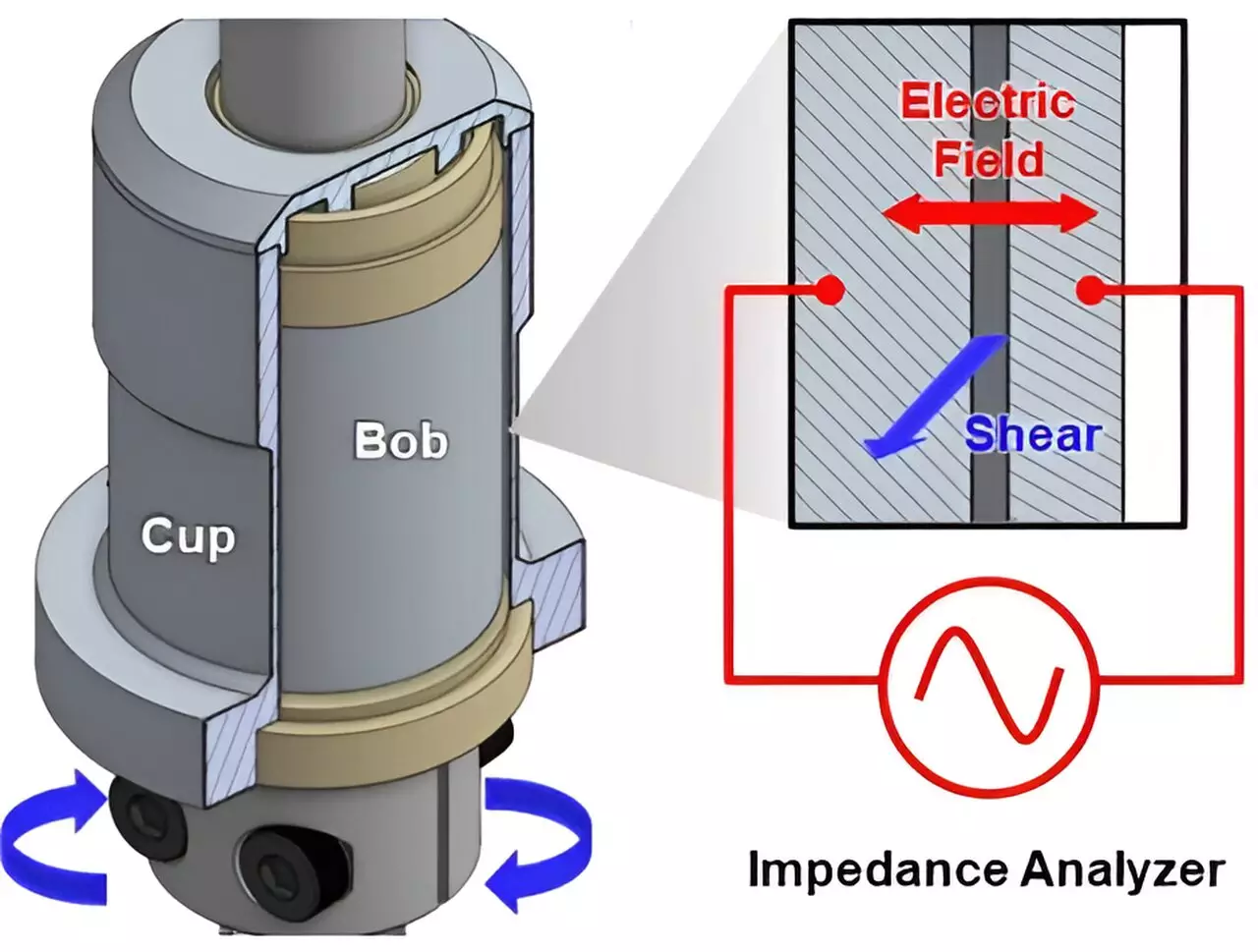

At the heart of many battery systems lies carbon black, a conductive material pivotal for creating effective slurries. Comprised of nano-sized carbon crystals that form clusters, this material must maintain its conductive properties despite being suspended in a liquid medium. Wagner explains that within this slurry, electrons exhibit rapid movement among clusters of carbon black, akin to a relay race. However, the challenge remains in the electrons’ necessity to ‘hop’ from one cluster to another, as these clusters do not form a continuous, solid framework. This phenomenon underscores the importance of understanding the flow properties, or rheology, of the slurry, which can significantly affect how efficiently these electrons operate.

The collective efforts of these researchers have resulted in what they describe as a “universal roadmap” for harnessing the conductivity of slurries, asserting that this blueprint could drive improved practices in electrochemical device manufacturing. This roadmap aims to systematically guide the design processes, allowing manufacturers to anticipate and optimize the behavior of their materials. Understanding how the structure of slurries influences efficiency is critical for advancing the field, as noted by Wagner, who recognizes that while the study does not directly resolve specific challenges facing current battery technologies, it paves the way for improved methodologies across various electrochemical applications.

Broader Implications and Future Directions

The implications of this research extend beyond traditional batteries, promising advancements in other domains such as electrolyzers—devices crucial for splitting water into hydrogen and oxygen. This innovative aspect is particularly timely given the rising interest in hydrogen as a sustainable energy resource. Wagner posits that achieving optimal performance in these systems relies heavily on proper processing techniques. He warns that even with the right chemistry, inadequate processing can derail efforts to realize desired efficiencies and effectiveness.

As we stand at the forefront of a new era in material science and electrochemical technology, the insights gained from this collaboration provide not merely a snapshot of the present landscape but also a foundation for future exploration. By continuing to decipher the complexities of electron movement and the interplay between materials and processing, researchers open new avenues that could lead to extraordinary advancements in energy storage and conversion technologies. Each discovery is a step closer to reconciling the dynamic relationship between scientific inquiry and practical application, ensuring that the promise of innovation remains undiminished.