NCM811 materials have emerged as critical components in the quest for high-energy density lithium-ion batteries. Comprising nickel, cobalt, and manganese, these materials boast a well-structured composition that theoretically enhances battery performance. However, the operational realities present challenges. One significant issue is the propensity for cracks to form in polycrystalline NCM materials due to stress during battery cycling. This degradation process severely impacts the longevity and efficiency of batteries, necessitating a deeper investigation into their structural and chemical behaviors throughout usage.

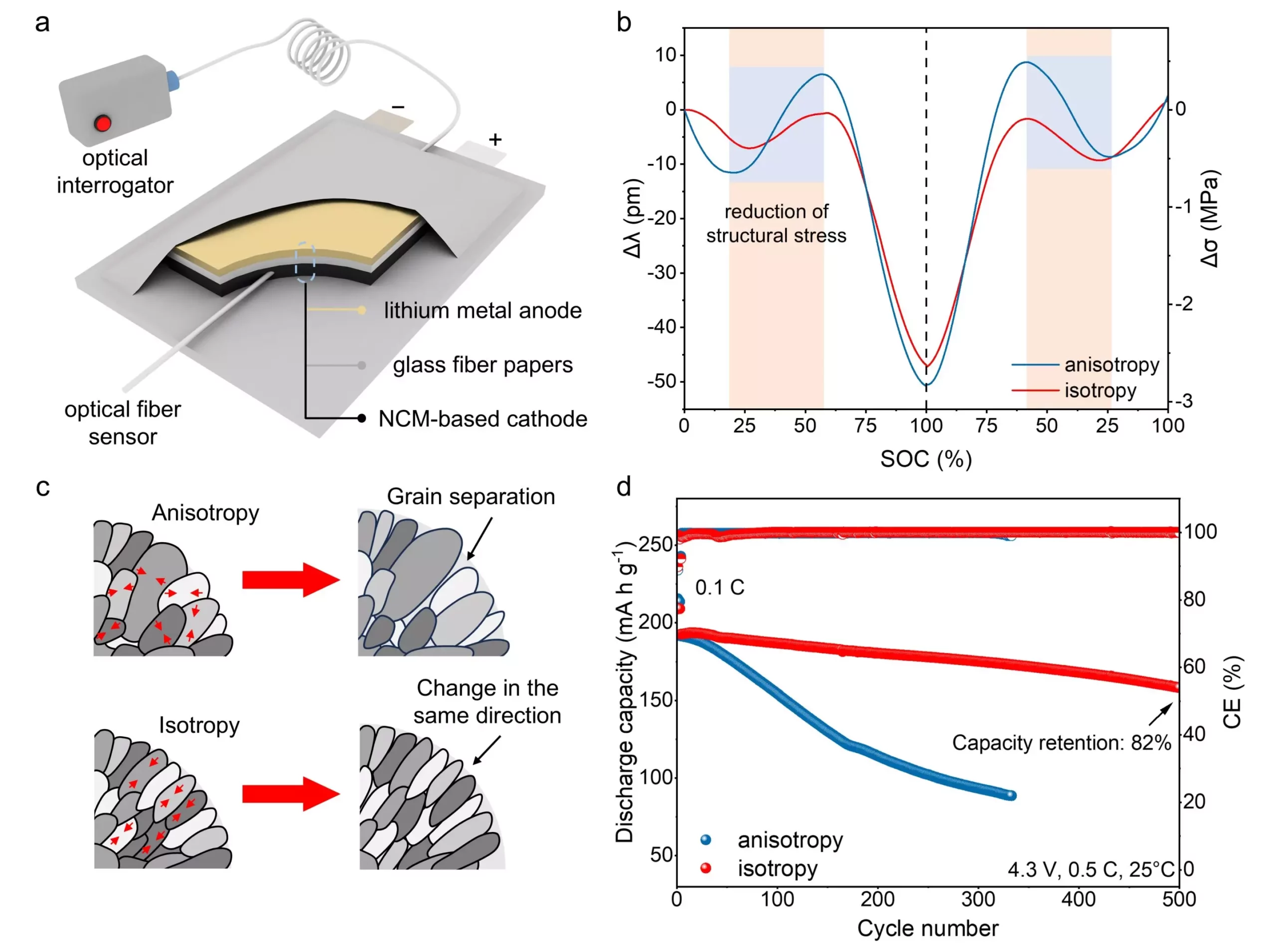

To tackle the critical issue of stress-induced cracks, a research team led by Prof. Yunhui Huang and Prof. Zhen Li has made a significant leap in monitoring the internal mechanics of NCM811. By integrating an optical fiber into the battery system, they have achieved in-operando detection of stress changes within the cathode material during operation. This approach offers real-time insights into how stress evolves, providing a clearer picture of the material’s integrity over time. The optical fiber’s small size and chemical stability ensure minimal interference with battery performance, thereby enhancing the reliability of sensing data.

The research identifies two primary types of stress affecting NCM811 materials: chemical stress and structural stress. Chemical stress arises during the (de)lithiation processes that are integral to battery function; it is an inherent, albeit manageable, aspect of battery operation. In contrast, structural stress poses a more critical risk as it can lead to the formation of cracks detrimental to battery performance. Understanding the genesis and impact of these cracks is essential for developing strategies to enhance battery life, thus informing materials engineering efforts moving forward.

The research reveals that the structural stress in polycrystalline NCM811 is primarily linked to the non-uniform changes in the c-axis dimensions of the crystals as lithium ions insert and extract. This phenomenon highlights the anisotropic nature of the primary particle arrangement, which can contribute to uneven stress distribution. To counteract these effects, the study proposes enhancing the anisotropy of the primary particles to foster a more ordered structural arrangement. This innovative approach has shown promising results, yielding a significant reduction in structural stress.

The advancements in optical sensing technologies hold considerable promise for the future of battery monitoring and performance optimization. As emphasized by Prof. Huang, the ability to decode the chemo-mechanical evolution of NCM materials could pave the way for designing batteries that are not only more efficient but also safer and smarter. Continuous advancements in sensing techniques could thus enhance the longevity of battery systems, reduce costs, and ultimately contribute to more sustainable energy solutions. With ongoing research in this field, the integration of advanced materials like NCM811 with innovative monitoring strategies may redefine the landscape of battery technology.