Bacteria, often vilified for their association with disease and decay, are now emerging as powerful allies in the quest for sustainable manufacturing. Notably, certain strains, including Komagataeibacter sucrofermentans, are capable of producing valuable materials such as cellulose, silk, and various minerals—all essential for numerous industries. The sustainable nature of bacterial production—operating effectively at room temperature and in aqueous environments—offers a significant environmental advantage. Yet, this potential comes with its own set of challenges. The slow growth rates and minimal yields of natural bacterial strains have historically hindered widespread industrial application. Innovating in this space could radically alter production processes across sectors, from biomedical applications to sustainable packaging.

Transforming Bacteria into Efficient Producers

Scientists have long sought to enhance the industrial viability of bacterial cellulose production through targeted genetic interventions and selective breeding techniques. In an unprecedented move, Professor André Studart and his team at ETH Zurich have introduced a novel methodology that harnesses evolutionary principles to effectively engineer bacterial strains. By rapidly generating thousands of distinct variants of K. sucrofermentans and then selecting those that exhibit superior cellulose production, the researchers are redefining what is possible in microbial manufacturing.

The groundwork for this ambitious approach was laid by Julie Laurent, a doctoral candidate whose innovative technique centers around inducing mutations through UV-C light exposure. This method damages DNA, creating a breeding ground for novel bacterial adaptations. Following this, Laurent encapsulated individual cells in droplets and measured cellulose output—automating the analysis and sorting process with remarkable efficiency. This scientific dance of selection and evolution allows for the swift identification and cultivation of bacteria that outperform their wild-type progenitors.

An Exciting Breakthrough in Cellulose Production

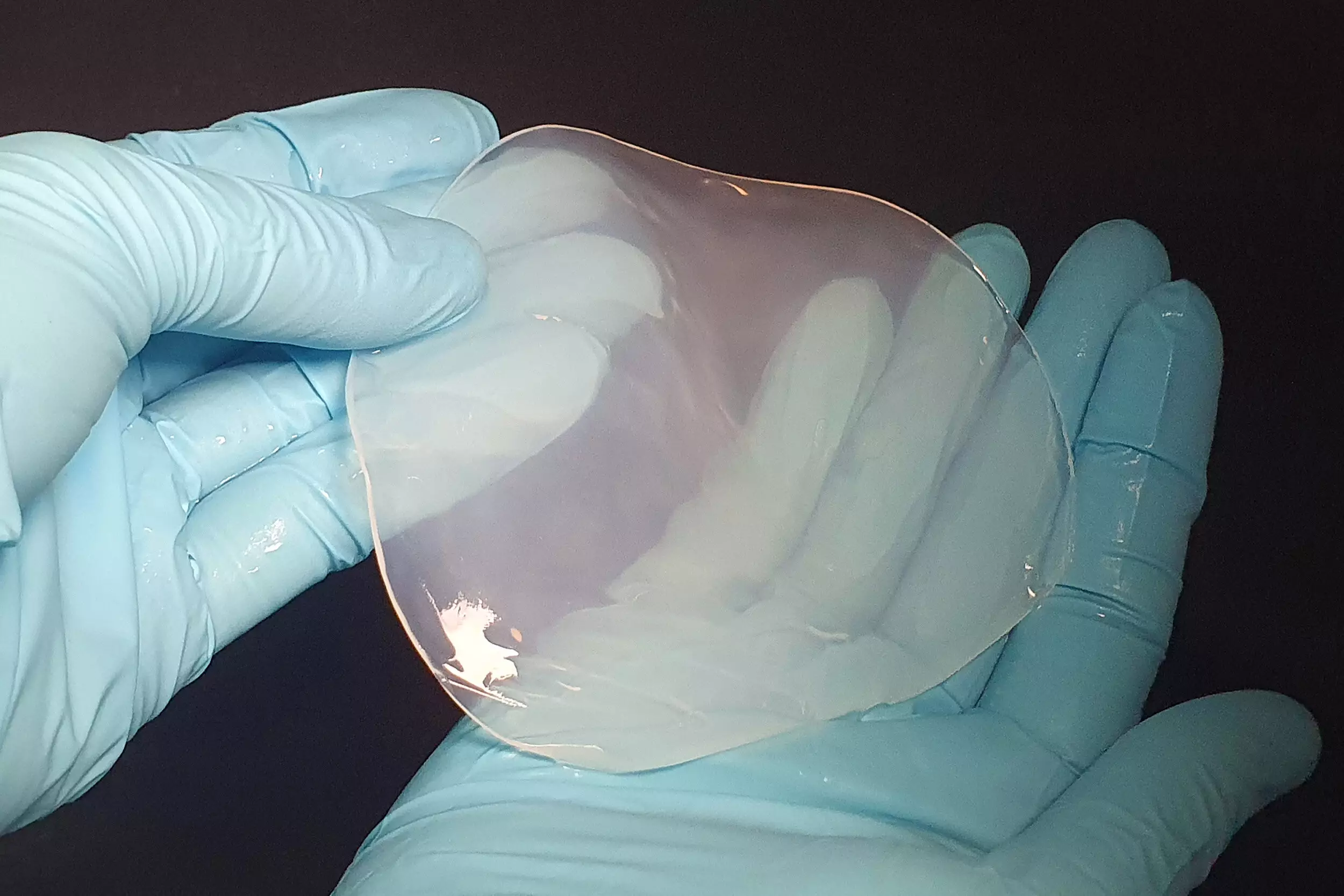

One of the most striking contributions of this research is the substantial increase in cellulose yield achieved by the newly developed bacterial variants. The engineered strains of K. sucrofermentans produced 50 to 70 percent more cellulose than the original strain, a significant leap that could have profound implications for industries reliant on this biopolymer. The cellulose produced is uniquely positioned for biomedical applications due to its roles in wound healing and infection prevention, making this research not only innovative but also impactful on global health.

Upon analysis, it was revealed that the mutations leading to the enhanced cellulose production stemmed from a single genetic alteration affecting a protease, an enzyme responsible for protein degradation. Surprisingly, the genes directly tied to cellulose biosynthesis remained relatively unchanged. This revelation hints at a complex regulatory mechanism wherein the protease may be modifying the proteins that control cellulose synthesis, thereby unleashing a greater production capacity. This serendipitous discovery elucidates not only the intricacies of microbial metabolism but also opens new avenues for manipulating bacterial behavior to boost material production.

The Path to Industrial Application

The implications of this method extend beyond just cellulose enhancement; it sets a precedent for future applications in engineering bacterial strains to produce other critical materials. Initially oriented towards producing proteins or enzymes, the approach now supports the creation of non-protein materials, demonstrating unprecedented versatility. The researchers, led by Professor Studart, consider this a monumental step in microbial engineering—a landmark achievement that could herald a new era in biomanufacturing.

Patents have been filed, and the team aims to transition their groundbreaking findings from the lab into real-world applications. Collaborating with companies that specialize in bacterial cellulose production could illuminate practical uses for the engineered variants. The prospect of scaling this technology could lead to a more sustainable manufacturing landscape, offering higher efficiency and lower environmental impacts.

Redefining the Future of Materials Science

The research conducted by Studart and his team reflects a broader trend in materials science; the urgency for sustainable alternatives is pushing researchers to innovate at the intersection of biology and technology. As humanity grapples with climate change and resource scarcity, these advancements offer a glimpse into a future where biological systems are harnessed to create essential materials in a more responsible and sustainable manner.

The ongoing exploration of microbial capabilities can redefine our understanding of production processes. Utilizing bacteria not just as agents of degradation but as active producers affirms a pivotal shift in materials science. The advancement representing K. sucrofermentans not only emphasizes the importance of research but also showcases how modern science can reshape industries for a more sustainable future. The potential of these living factories may very well alter the course of sustainable development—one droplet at a time.